98 XJ LDP where the hell is it??

#2

Seasoned Member

Joined: Sep 2013

Posts: 362

Likes: 1

From: LI, NY

Year: 2000

Model: Cherokee

Engine: 4.0

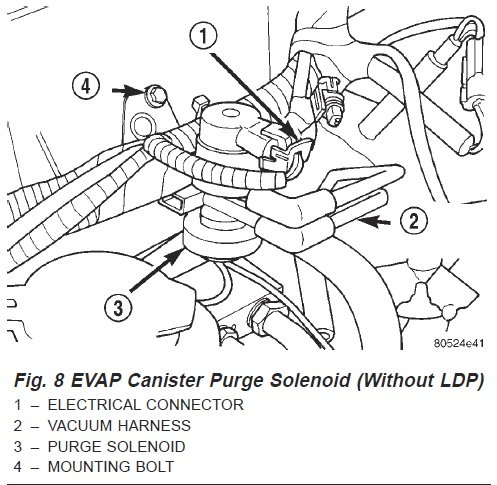

Im not sure if its what youre referring to but theres a purge canister thing under the truck above the rear axle bolted to the floorboards. I think 97 was the first year it was located there.

#4

CF Veteran

Joined: Aug 2010

Posts: 8,357

Likes: 90

From: Canton, MI

Year: 1999

Model: Cherokee

Engine: 4.0

#7

CF Veteran

Joined: Aug 2010

Posts: 8,357

Likes: 90

From: Canton, MI

Year: 1999

Model: Cherokee

Engine: 4.0

Look for it.

Trending Topics

#11

CF Veteran

Joined: Aug 2010

Posts: 8,357

Likes: 90

From: Canton, MI

Year: 1999

Model: Cherokee

Engine: 4.0

Clear as mud:

LEAK DETECTION PUMP (LDP) OPERATION

The Leak Detection Pump (LDP) is used only with certain emission packages.

The LDP is a device used to detect a leak in the evaporative system.

The pump contains a 3 port solenoid, a pump that contains a switch, a spring loaded canister vent valve seal, 2 check valves and a spring/diaphragm.

Immediately after a cold start, engine temperature between 40°F and 86°F, the 3 port solenoid is briefly energized. This initializes the pump by drawing air into the pump cavity and also closes the vent seal. During non-test test conditions, the vent seal is held open by the pump diaphragm assembly which pushes it open at the full travel position. The vent seal will remain closed while the pump is cycling. This is due to the operation of the 3 port solenoid which prevents the diaphragm assembly from reaching full travel.

After the brief initialization period, the solenoid is de-energized, allowing atmospheric pressure to enter the pump cavity. This permits the spring to drive the diaphragm which forces air out of the pump cavity and into the vent system. When the solenoid is energized and de-energized, the cycle is repeated creating flow in typical diaphragm pump fashion. The pump is controlled in 2 modes:

PUMP MODE: The pump is cycled at a fixed rate to achieve a rapid pressure build in order to shorten the overall test time.

TEST MODE: The solenoid is energized with a fixed duration pulse. Subsequent fixed pulses occur when the diaphragm reaches the switch closure point.

The spring in the pump is set so that the system will achieve an equalized pressure of about 7.5 inches of water. When the pump starts, the cycle rate is quite high. As the system becomes pressurized pump rate drops.

If there is no leak the pump will quit. If there is a leak, the test is terminated at the end of the test mode. If there is no leak, the purge monitor is run. If the cycle rate increases due to the flow through the purge system, the test is passed and the diagnostic is complete.

The canister vent valve will unseal the system after completion of the test sequence as the pump diaphragm assembly moves to the full travel position.

LEAK DETECTION PUMP (LDP) OPERATION

The Leak Detection Pump (LDP) is used only with certain emission packages.

The LDP is a device used to detect a leak in the evaporative system.

The pump contains a 3 port solenoid, a pump that contains a switch, a spring loaded canister vent valve seal, 2 check valves and a spring/diaphragm.

Immediately after a cold start, engine temperature between 40°F and 86°F, the 3 port solenoid is briefly energized. This initializes the pump by drawing air into the pump cavity and also closes the vent seal. During non-test test conditions, the vent seal is held open by the pump diaphragm assembly which pushes it open at the full travel position. The vent seal will remain closed while the pump is cycling. This is due to the operation of the 3 port solenoid which prevents the diaphragm assembly from reaching full travel.

After the brief initialization period, the solenoid is de-energized, allowing atmospheric pressure to enter the pump cavity. This permits the spring to drive the diaphragm which forces air out of the pump cavity and into the vent system. When the solenoid is energized and de-energized, the cycle is repeated creating flow in typical diaphragm pump fashion. The pump is controlled in 2 modes:

PUMP MODE: The pump is cycled at a fixed rate to achieve a rapid pressure build in order to shorten the overall test time.

TEST MODE: The solenoid is energized with a fixed duration pulse. Subsequent fixed pulses occur when the diaphragm reaches the switch closure point.

The spring in the pump is set so that the system will achieve an equalized pressure of about 7.5 inches of water. When the pump starts, the cycle rate is quite high. As the system becomes pressurized pump rate drops.

If there is no leak the pump will quit. If there is a leak, the test is terminated at the end of the test mode. If there is no leak, the purge monitor is run. If the cycle rate increases due to the flow through the purge system, the test is passed and the diagnostic is complete.

The canister vent valve will unseal the system after completion of the test sequence as the pump diaphragm assembly moves to the full travel position.

The following users liked this post:

ChromeToaster (02-02-2024)

#12

Banned

Joined: Feb 2014

Posts: 2,379

Likes: 17

From: Florida

Year: 2000

Model: Cherokee(XJ)

Engine: Golen 4.6L

If I'm reading that correctly, the short version is that the LDP pumps air into the system, and the LDP monitor checks the pressure to see if there is a leak. If the system loses pressure, the test fails. The computer then records the failure. I don't know if that results in a CEL or just a failed emissions item. It's basically checking to make sure that the evaporative system is pressurized, whereas on EPA vehicles nobody cares.

#13

CF Veteran

Joined: Aug 2010

Posts: 8,357

Likes: 90

From: Canton, MI

Year: 1999

Model: Cherokee

Engine: 4.0

If I'm reading that correctly, the short version is that the LDP pumps air into the system, and the LDP monitor checks the pressure to see if there is a leak. If the system loses pressure, the test fails. The computer then records the failure. I don't know if that results in a CEL or just a failed emissions item. It's basically checking to make sure that the evaporative system is pressurized, whereas on EPA vehicles nobody cares.

P0442-EVAP LEAK MONITOR MEDIUM (0.040) LEAK DETECTED

P0455-EVAP LEAK MONITOR LARGE LEAK DETECTED

P0455-EVAP LEAK MONITOR LARGE LEAK DETECTED

P0456-EVAP LEAK MONITOR SMALL LEAK DETECTED (.020)

Edit: A few more LDP related DTC's:

P1486-EVAP LEAK MONITOR PINCHED HOSE FOUND

P1494-LEAK DETECTION PUMP SW OR MECHANICAL FAULT

P1495-LEAK DETECTION PUMP SOLENOID CIRCUIT

P1494-LEAK DETECTION PUMP SW OR MECHANICAL FAULT

P1495-LEAK DETECTION PUMP SOLENOID CIRCUIT

Last edited by CCKen; 01-02-2015 at 12:08 PM.

#14

Banned

Joined: Feb 2014

Posts: 2,379

Likes: 17

From: Florida

Year: 2000

Model: Cherokee(XJ)

Engine: Golen 4.6L

Here's the DTC's that will be stored:

P0456-EVAP LEAK MONITOR SMALL LEAK DETECTED (.020)

Edit: A few more LDP related DTC's:

P0442-EVAP LEAK MONITOR MEDIUM (0.040) LEAK DETECTED

P0455-EVAP LEAK MONITOR LARGE LEAK DETECTED

P0455-EVAP LEAK MONITOR LARGE LEAK DETECTED

P0456-EVAP LEAK MONITOR SMALL LEAK DETECTED (.020)

Edit: A few more LDP related DTC's:

P1486-EVAP LEAK MONITOR PINCHED HOSE FOUND

P1494-LEAK DETECTION PUMP SW OR MECHANICAL FAULT

P1495-LEAK DETECTION PUMP SOLENOID CIRCUIT

P1494-LEAK DETECTION PUMP SW OR MECHANICAL FAULT

P1495-LEAK DETECTION PUMP SOLENOID CIRCUIT

#15

CF Veteran

Joined: Aug 2010

Posts: 8,357

Likes: 90

From: Canton, MI

Year: 1999

Model: Cherokee

Engine: 4.0

Thread

Thread Starter

Forum

Replies

Last Post

carverdave

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

8

09-01-2024 09:55 AM

TheDesertlights

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

9

08-04-2016 11:13 AM

Crazynut1997

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

15

09-29-2015 09:14 PM

ZombieResponseJeep

Stock Grand Cherokee Tech. All ZJ/WJ/WK Non-modified/stock questions go here!

8

09-22-2015 09:45 AM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)