99 PCM replace/update

#106

CF Veteran

Not really. The thought that CPS location can have a bearing on signal strength has been detailed in Renix by Cruiser (see Tip #7).

Is this applicable to OBDI/OBDII CPSs? Well, we're kinda running out of things to look at. I imagine no one considered this because the vehicle was "professionally tested" and the cam and crank sensors were found to be in sync. But if the CPS doesn't see a shutter window clearly (because it is seeing mostly metal), then it may not be generating high enough voltage. Enough of one so that the all functions are normal, but not high enough for ECU to consider it normal.

Is this applicable to OBDI/OBDII CPSs? Well, we're kinda running out of things to look at. I imagine no one considered this because the vehicle was "professionally tested" and the cam and crank sensors were found to be in sync. But if the CPS doesn't see a shutter window clearly (because it is seeing mostly metal), then it may not be generating high enough voltage. Enough of one so that the all functions are normal, but not high enough for ECU to consider it normal.

#107

CF Veteran

Thread Starter

Join Date: Jun 2016

Location: CO

Posts: 1,011

Likes: 0

Received 20 Likes

on

18 Posts

Year: 99

Model: Cherokee (XJ)

Engine: 4.0

Not really. The thought that CPS location can have a bearing on signal strength has been detailed in Renix by Cruiser (see Tip #7).

Is this applicable to OBDI/OBDII CPSs? Well, we're kinda running out of things to look at. I imagine no one considered this because the vehicle was "professionally tested" and the cam and crank sensors were found to be in sync. But if the CPS doesn't see a shutter window clearly (because it is seeing mostly metal), then it may not be generating high enough voltage. Enough of one so that the all functions are normal, but not high enough for ECU to consider it normal.

Is this applicable to OBDI/OBDII CPSs? Well, we're kinda running out of things to look at. I imagine no one considered this because the vehicle was "professionally tested" and the cam and crank sensors were found to be in sync. But if the CPS doesn't see a shutter window clearly (because it is seeing mostly metal), then it may not be generating high enough voltage. Enough of one so that the all functions are normal, but not high enough for ECU to consider it normal.

#108

CF Veteran

Whatcha thinking?

Hey, you wanted "out of the box"? This is "out of the box"!

#109

CF Veteran

Thread Starter

Join Date: Jun 2016

Location: CO

Posts: 1,011

Likes: 0

Received 20 Likes

on

18 Posts

Year: 99

Model: Cherokee (XJ)

Engine: 4.0

I know. See my above post why it's that particular pattern.

Yes, that was in regards to xjjeery suggesting thermal sensitivity.

That the sensor is not seeing the shutters clearly. Unfortunately, we (you) can't see that the CPS isn't seeing that. Read the cruiser tip and see how and what the output voltage of CPS is. Then we have to guess. If you take off the CPS and put about 1/16" of washers to move it out a little that may make it see more window. You could drill out the CPS holes to be able to close the air gap, but again, IMO right now it's seeing too much metal.

Hey, you wanted "out of the box"? This is "out of the box"!

Yes, that was in regards to xjjeery suggesting thermal sensitivity.

That the sensor is not seeing the shutters clearly. Unfortunately, we (you) can't see that the CPS isn't seeing that. Read the cruiser tip and see how and what the output voltage of CPS is. Then we have to guess. If you take off the CPS and put about 1/16" of washers to move it out a little that may make it see more window. You could drill out the CPS holes to be able to close the air gap, but again, IMO right now it's seeing too much metal.

Hey, you wanted "out of the box"? This is "out of the box"!

#111

CF Veteran

We could do this a lot more scientifically if you pulled the engine and tranny out so we could bench test this...

#112

CF Veteran

Thread Starter

Join Date: Jun 2016

Location: CO

Posts: 1,011

Likes: 0

Received 20 Likes

on

18 Posts

Year: 99

Model: Cherokee (XJ)

Engine: 4.0

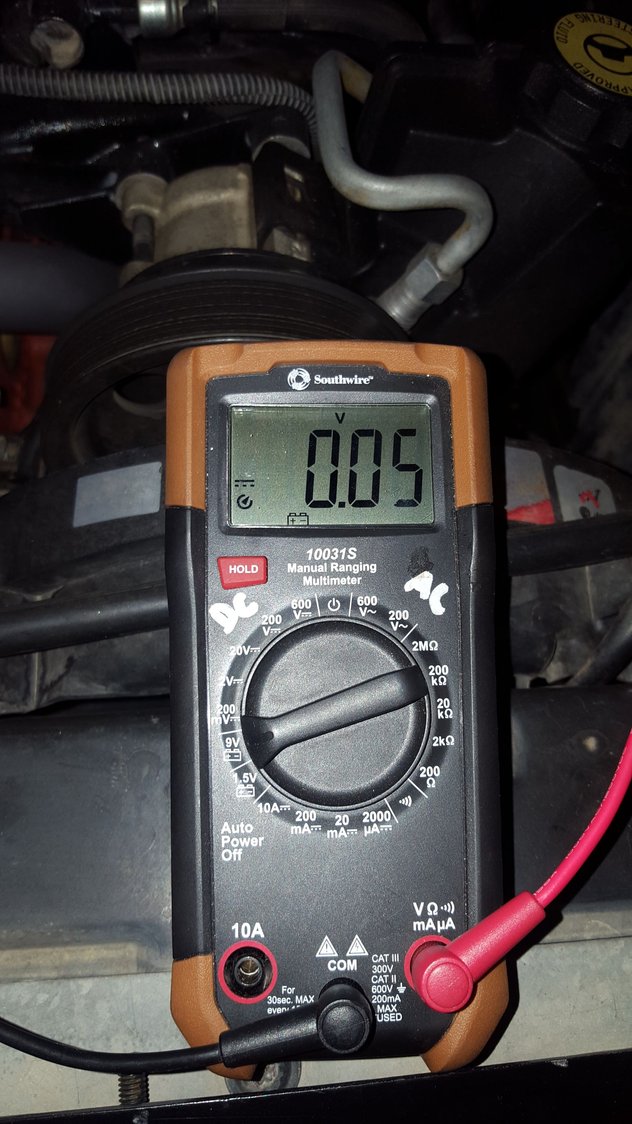

i will Re try Awgs clear the adaptive memory with the headlights and re start and ill get a voltage reading from a key on- and turn the crank until ckps is reading the flex plate. i believe i did this already, but i cant recall what the reading was.

#113

CF Veteran

Join Date: Mar 2016

Posts: 3,551

Received 663 Likes

on

566 Posts

Year: 96

Model: Cherokee (XJ)

Engine: 4.0

now that cant happen lol, this is a daily driver.

i will Re try Awgs clear the adaptive memory with the headlights and re start and ill get a voltage reading from a key on- and turn the crank until ckps is reading the flex plate. i believe i did this already, but i cant recall what the reading was.

i will Re try Awgs clear the adaptive memory with the headlights and re start and ill get a voltage reading from a key on- and turn the crank until ckps is reading the flex plate. i believe i did this already, but i cant recall what the reading was.

..even though I doubt it is the problem (as the pros would use a code scanner)...all bets are off until you use a $20 scanner plugged into your OBD2 port to clear codes & CEL..no other method is satisfactory imo

apart from that, from what you have said, you would have eliminated the PCM, open wires, and some connectors, you have changed Crank and Cam sensors...engine timing is all but ruled out

so what does that leave not ruled out ?..imo, the following...flexplate, intermittent shorts, PCM connector

All pretty time consuming to verify...I am sure it is no consolation to you that this can happen to pro mechanics and dealers too (as you have found out)

If you wish for further advice on checking the PCM connector/harness. or for intermitent shorts, I can provide some procedures

#115

CF Veteran

Here's another thought (I have never tried this, but it's cheap and you'll end up with a helpful tool). Get a flexible USB camera and see if you can visualize the position of the CPS over the flexplate reluctors.

#118

CF Veteran

Watch this video to see the waveform of a misreading crank sensor on a Dodge Avenger. (pretty similar, cam and crank signals) You can't tell the story with your DMM.

-

-

#119

CF Veteran

Join Date: Mar 2016

Posts: 3,551

Received 663 Likes

on

566 Posts

Year: 96

Model: Cherokee (XJ)

Engine: 4.0

ok, let us clarify a couple more things before we go down the more radical paths

firstly, there is no point wasting any more time till you have confirmed PCM codes cleared with an OBD2 scanner..and that scanner then reads "no codes"

Ignoring the flexplate, even though I think it has to be considered the prime suspect, and concentrating on an "intermitent short or open"

Can you confirm your truck has absolutely no symptoms, misfire etc ?

Clearly you must fix this to pass a registration law to do with CEL light or codes?...not just because you want to ?

In the instance of a intermitent open wire problem,,,, that is known to exist in jeeps, however, concentrating on the connectors, especially female pins

You need a few things..to examine each pin and recess under magnification and strong light for any sign of loose, recessed, corroded or otherwise suspect issue..I have magnifying glasses, and a Jewellers loupe

carefully clean each pin and see if it wiggles, using contact cleaner, i use cut wound guitar strings, various OD

I want to say this is tricky work..in most cases, individual wires within a plug can be backed out of the plug using a special tool...they also can get accidentally loosened, mainly by plugging & unplugging connectors

It helps to have an assistant for the next stage which is to test the harness for intermittent opens, by unplugging it, testing continuity with a test light while flexing the wires

the final issue of testing for shorts is gruesome indeed, as you have to cut the factory wires, one by one, and re-solder when tested

it helps to have good test leads made with alligator clips, and test probes, although safety pins do work fine

even though it doesnt make a lot of sense, I am working on the assumption your crank or cam sensor signal is dropping out every so often...I expect that would cause a misfire though, even if ever so slight ??

firstly, there is no point wasting any more time till you have confirmed PCM codes cleared with an OBD2 scanner..and that scanner then reads "no codes"

Ignoring the flexplate, even though I think it has to be considered the prime suspect, and concentrating on an "intermitent short or open"

Can you confirm your truck has absolutely no symptoms, misfire etc ?

Clearly you must fix this to pass a registration law to do with CEL light or codes?...not just because you want to ?

In the instance of a intermitent open wire problem,,,, that is known to exist in jeeps, however, concentrating on the connectors, especially female pins

You need a few things..to examine each pin and recess under magnification and strong light for any sign of loose, recessed, corroded or otherwise suspect issue..I have magnifying glasses, and a Jewellers loupe

carefully clean each pin and see if it wiggles, using contact cleaner, i use cut wound guitar strings, various OD

I want to say this is tricky work..in most cases, individual wires within a plug can be backed out of the plug using a special tool...they also can get accidentally loosened, mainly by plugging & unplugging connectors

It helps to have an assistant for the next stage which is to test the harness for intermittent opens, by unplugging it, testing continuity with a test light while flexing the wires

the final issue of testing for shorts is gruesome indeed, as you have to cut the factory wires, one by one, and re-solder when tested

it helps to have good test leads made with alligator clips, and test probes, although safety pins do work fine

even though it doesnt make a lot of sense, I am working on the assumption your crank or cam sensor signal is dropping out every so often...I expect that would cause a misfire though, even if ever so slight ??

#120

CF Veteran

Thread Starter

Join Date: Jun 2016

Location: CO

Posts: 1,011

Likes: 0

Received 20 Likes

on

18 Posts

Year: 99

Model: Cherokee (XJ)

Engine: 4.0

ok, let us clarify a couple more things before we go down the more radical paths

firstly, there is no point wasting any more time till you have confirmed PCM codes cleared with an OBD2 scanner..and that scanner then reads "no codes"

Ignoring the flexplate, even though I think it has to be considered the prime suspect, and concentrating on an "intermitent short or open"

Can you confirm your truck has absolutely no symptoms, misfire etc ?

Clearly you must fix this to pass a registration law to do with CEL light or codes?...not just because you want to ?

In the instance of a intermitent open wire problem,,,, that is known to exist in jeeps, however, concentrating on the connectors, especially female pins

You need a few things..to examine each pin and recess under magnification and strong light for any sign of loose, recessed, corroded or otherwise suspect issue..I have magnifying glasses, and a Jewellers loupe

carefully clean each pin and see if it wiggles, using contact cleaner, i use cut wound guitar strings, various OD

I want to say this is tricky work..in most cases, individual wires within a plug can be backed out of the plug using a special tool...they also can get accidentally loosened, mainly by plugging & unplugging connectors

It helps to have an assistant for the next stage which is to test the harness for intermittent opens, by unplugging it, testing continuity with a test light while flexing the wires

the final issue of testing for shorts is gruesome indeed, as you have to cut the factory wires, one by one, and re-solder when tested

it helps to have good test leads made with alligator clips, and test probes, although safety pins do work fine

even though it doesnt make a lot of sense, I am working on the assumption your crank or cam sensor signal is dropping out every so often...I expect that would cause a misfire though, even if ever so slight ??

firstly, there is no point wasting any more time till you have confirmed PCM codes cleared with an OBD2 scanner..and that scanner then reads "no codes"

Ignoring the flexplate, even though I think it has to be considered the prime suspect, and concentrating on an "intermitent short or open"

Can you confirm your truck has absolutely no symptoms, misfire etc ?

Clearly you must fix this to pass a registration law to do with CEL light or codes?...not just because you want to ?

In the instance of a intermitent open wire problem,,,, that is known to exist in jeeps, however, concentrating on the connectors, especially female pins

You need a few things..to examine each pin and recess under magnification and strong light for any sign of loose, recessed, corroded or otherwise suspect issue..I have magnifying glasses, and a Jewellers loupe

carefully clean each pin and see if it wiggles, using contact cleaner, i use cut wound guitar strings, various OD

I want to say this is tricky work..in most cases, individual wires within a plug can be backed out of the plug using a special tool...they also can get accidentally loosened, mainly by plugging & unplugging connectors

It helps to have an assistant for the next stage which is to test the harness for intermittent opens, by unplugging it, testing continuity with a test light while flexing the wires

the final issue of testing for shorts is gruesome indeed, as you have to cut the factory wires, one by one, and re-solder when tested

it helps to have good test leads made with alligator clips, and test probes, although safety pins do work fine

even though it doesnt make a lot of sense, I am working on the assumption your crank or cam sensor signal is dropping out every so often...I expect that would cause a misfire though, even if ever so slight ??