A/C Recharge FAIL

#1

Thread Starter

No, I don't lick fish.

Joined: Mar 2011

Posts: 11,167

Likes: 21

From: Northern Kentucky

Year: 1999

Model: Cherokee (XJ)

Engine: 4.0

Need some help from the A/C techs here.

I have a 1992 Cherokee with the Sanden compressor. It has just enough freon in it to make the compressor kick on, but not enough to really cool the air down. The system already has the 134 fitting on it.

The problem is, the fill valve (I guess that's what you'd call it) that these compressors have apparently has to be opened for you to put anything in it or even to do a pressure check. It won't open... I would assume it's a standard counter-clockwise motion to open it, but it won't budge either way. I've tried opened-end wrenches, pliers, and even vice-grips and it won't turn.

What am I doing wrong?

I have a 1992 Cherokee with the Sanden compressor. It has just enough freon in it to make the compressor kick on, but not enough to really cool the air down. The system already has the 134 fitting on it.

The problem is, the fill valve (I guess that's what you'd call it) that these compressors have apparently has to be opened for you to put anything in it or even to do a pressure check. It won't open... I would assume it's a standard counter-clockwise motion to open it, but it won't budge either way. I've tried opened-end wrenches, pliers, and even vice-grips and it won't turn.

What am I doing wrong?

#2

If it's already been converted to 134, the fittings are just snap locks. Press the connector down on the gauge set and release the lock ring. Shouldn't have to turn anything.

Do you have a picture of the fitting causing problems?

Do you have a picture of the fitting causing problems?

#3

Thread Starter

No, I don't lick fish.

Joined: Mar 2011

Posts: 11,167

Likes: 21

From: Northern Kentucky

Year: 1999

Model: Cherokee (XJ)

Engine: 4.0

I'm at work right now so I'll snap pics tomorrow. The fitting isn't the problem, it's the open/close valve attached to the line at the compressor that is the problem. Fitting seems to work fine. I can snap the recharge kit line on it without any problem. I've tried several hoses just to rule out the re-charge kit hose. So I know that's not it.

Might have to just wait until I get a pic up to see what I'm talking about.

Might have to just wait until I get a pic up to see what I'm talking about.

#4

I believe what you're trying to turn is part of the accumulator and not a valve. It's one piece and isn't supposed to turn. Are you certain that after you snapped on the refill hose you opened the R134 can? It's a twist valve that punctures the top of the can. The pressure gauge wont give you a reading until that can is punctured.

#6

Thread Starter

No, I don't lick fish.

Joined: Mar 2011

Posts: 11,167

Likes: 21

From: Northern Kentucky

Year: 1999

Model: Cherokee (XJ)

Engine: 4.0

I'll have to take a look... there are two of them... one for the low side, one for the high side... I believe they are part of the actual lines, but I'll have to look again.

#7

Thread Starter

No, I don't lick fish.

Joined: Mar 2011

Posts: 11,167

Likes: 21

From: Northern Kentucky

Year: 1999

Model: Cherokee (XJ)

Engine: 4.0

I believe what you're trying to turn is part of the accumulator and not a valve. It's one piece and isn't supposed to turn. Are you certain that after you snapped on the refill hose you opened the R134 can? It's a twist valve that punctures the top of the can. The pressure gauge wont give you a reading until that can is punctured.

Trending Topics

#8

You just had it converted the to R134 from R12 correct? And now have 90 dregee fittings? Or just the standard straight up fittings? If I'm correct the 1/4 valve turns counter clockwise. Clockwise closes them. In order to service the system you have to open them up half way to drain or fill. Opening them up all the way let's you isolate the compressor to add oil/dye right after vacuuming down and before filling. So connecting your gauges, open half way counter, open low side (gauge side) and fill then close gauges and obeserve readings till about a 35-45 low side and a 2.2/2.5 outside temp so should leave you around 175-250 more or less. Close valves clockwise and enjoy air once again. Oh and don't forget to tighten lines up unless have changes the o rings out already but another tighten won't hurt. No smoke just tight.

#9

Member

Joined: Apr 2011

Posts: 106

Likes: 0

From: North Texas

Year: 1992

Model: Cherokee

Engine: 4.0 HO

The service valve really only needs to be "cracked" open.....no more than a half turn or so....they make a special ratchet type wrench...its a square drive.....if you havent already rounded it off....you might be able to find one at a pawn shop....I can take a picture of one if you want to see it....a trick I used to use when I did commercial refrigeration work and had a service valve stuck was to put the service valve wrench on the stem, apply pressure and rap the valve with a crescent wrench or similar.....would let loose most every time....

#10

Thread Starter

No, I don't lick fish.

Joined: Mar 2011

Posts: 11,167

Likes: 21

From: Northern Kentucky

Year: 1999

Model: Cherokee (XJ)

Engine: 4.0

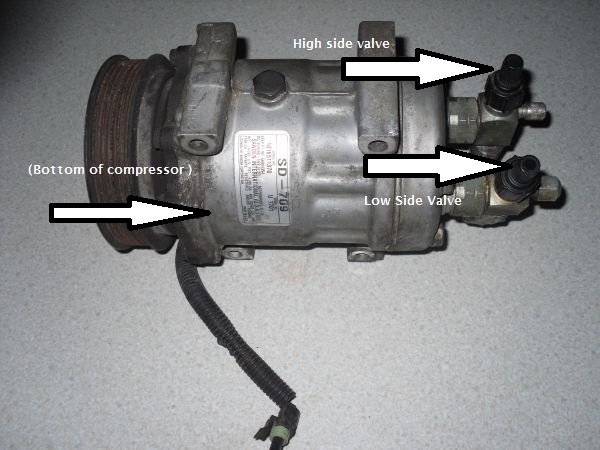

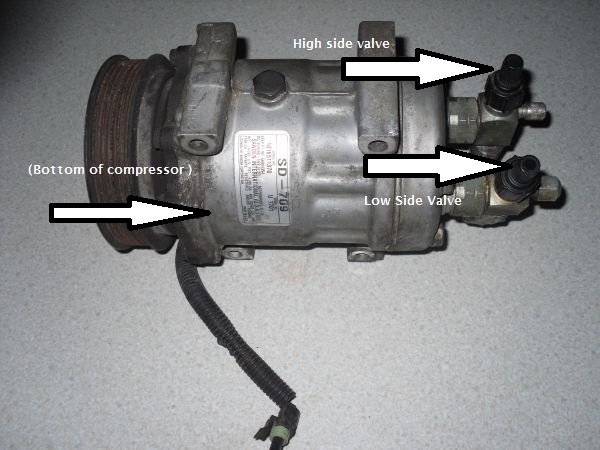

Found a picture online of the compressor. It's not mounted, but still should give you guys an idea of what I'm talking about... kinda hard to tell, but the black things coming out of the back are the valves that you have to turn

#11

Thread Starter

No, I don't lick fish.

Joined: Mar 2011

Posts: 11,167

Likes: 21

From: Northern Kentucky

Year: 1999

Model: Cherokee (XJ)

Engine: 4.0

You just had it converted the to R134 from R12 correct? And now have 90 dregee fittings? Or just the standard straight up fittings? If I'm correct the 1/4 valve turns counter clockwise. Clockwise closes them. In order to service the system you have to open them up half way to drain or fill. Opening them up all the way let's you isolate the compressor to add oil/dye right after vacuuming down and before filling. So connecting your gauges, open half way counter, open low side (gauge side) and fill then close gauges and obeserve readings till about a 35-45 low side and a 2.2/2.5 outside temp so should leave you around 175-250 more or less. Close valves clockwise and enjoy air once again. Oh and don't forget to tighten lines up unless have changes the o rings out already but another tighten won't hurt. No smoke just tight.

The service valve really only needs to be "cracked" open.....no more than a half turn or so....they make a special ratchet type wrench...its a square drive.....if you havent already rounded it off....you might be able to find one at a pawn shop....I can take a picture of one if you want to see it....a trick I used to use when I did commercial refrigeration work and had a service valve stuck was to put the service valve wrench on the stem, apply pressure and rap the valve with a crescent wrench or similar.....would let loose most every time....

#13

Thread Starter

No, I don't lick fish.

Joined: Mar 2011

Posts: 11,167

Likes: 21

From: Northern Kentucky

Year: 1999

Model: Cherokee (XJ)

Engine: 4.0

Yeah, I know it... friggin' thing. I really don't wanna lose the vacuum, but if I have to, I'll just replace the stupid valve. I reeeeeaaaaaalllly don't wanna, but man it sure is hot in FL right now. I can't do another full summer driving it to work and needing a shower by the time I get there.

#14

Originally Posted by Basslicks

Found a picture online of the compressor. It's not mounted, but still should give you guys an idea of what I'm talking about... kinda hard to tell, but the black things coming out of the back are the valves that you have to turn

#15

Senior Member

Joined: Jun 2012

Posts: 595

Likes: 0

From: Rome, GA

Year: 1990

Model: Cherokee

Engine: 4.0

My A/C compressor has the same valves on it although, mine are on top rather than on the end. I did a little research before I retrofitted mine. The normal operating position for those valves is backseated. This means the valve is turned fully counterclockwise. This position has the compressor connected to the A/C system but, the recovery/charge ports blocked off.

To open them, you have to turn them about half a turn (180 degrees) or so clockwise BUT, you need to have your A/C hoses connected first because there are no valve cores in the OE fittings.

Turning the valves fully clockwise (frontseated) will lockout the compressor so that the oil level can be checked without losing refrigerant.

I was going to post a pic but, photo bucket is down at the moment.

To open them, you have to turn them about half a turn (180 degrees) or so clockwise BUT, you need to have your A/C hoses connected first because there are no valve cores in the OE fittings.

Turning the valves fully clockwise (frontseated) will lockout the compressor so that the oil level can be checked without losing refrigerant.

I was going to post a pic but, photo bucket is down at the moment.