Does this auto trans problem diagnosis sound legit?

#16

Thread Starter

CF Veteran

Joined: Jan 2014

Posts: 1,349

Likes: 287

From: District of Columbia

Year: 1998

Model: Cherokee (XJ)

Engine: 4.0

What's the CCD bus? It drove like it normally does, that is with the shifting issues. No gauges and the airbag light is on. I'll plug the cluster back in before I pull out the multimeter.

#17

CF Veteran

Joined: Aug 2010

Posts: 8,357

Likes: 90

From: Canton, MI

Year: 1999

Model: Cherokee

Engine: 4.0

I can understand not having instruments but if the cluster wasn't plugged in how did you have an airbag light on?

The CCD Bus is the Chrysler Crash Detection Bus. Nothing to do with a "Crash", it is the communication network for all modules on the Bus.

Here's a schematic that shows all the modules on the Bus:

Here's an explanation of hoe the Bus works:

The CCD Bus is the Chrysler Crash Detection Bus. Nothing to do with a "Crash", it is the communication network for all modules on the Bus.

Here's a schematic that shows all the modules on the Bus:

Here's an explanation of hoe the Bus works:

#18

Thread Starter

CF Veteran

Joined: Jan 2014

Posts: 1,349

Likes: 287

From: District of Columbia

Year: 1998

Model: Cherokee (XJ)

Engine: 4.0

What I can tell you is the tech told me he found the TCU was not communicating with the scan tool, and he did some voltage checks and found 2 wires going to the cluster from the bus that had 2.47 volts with no fluctuation. He disconnected these wires to the cluster and the shifting problems stopped, though I found on my drive home this was not the case. I think that's how he diagnosed the open circuit in the cluster as the culprit. I'm going to plug everything back in a and test the solenoid circuits now.

#19

Thread Starter

CF Veteran

Joined: Jan 2014

Posts: 1,349

Likes: 287

From: District of Columbia

Year: 1998

Model: Cherokee (XJ)

Engine: 4.0

I plugged the two wires leading to the cluster back into what appears to be the bus test port(?). Here's a picture. It's under the steering column to the left. The tech had one of each color wire removed (one is white with black, the other is purple. By the way, that sticker says ELECT TEST.

With those back in, the cluster now seems to operate correctly again. I was getting a P0175 code for faulty trans input/output sensor, but I suspect that may have been from having the cluster wires disconnected. I cleared the codes and drove around, and all I'm getting now is the usual P0700 and P0753 I've had from the beginning.

I then tried unplugging the TCM per the other thread you posted and manually shifting through the gears. Evertyhing seems to work fine, that is, I only get 1st gear in 1-2, only 3rd in 3, and only 4th in D. Of course with the TCM unplugged I get P0700 and P1698 codes.

Now I'll try the voltage tests from the TCM connector as you recommend. I'll post those results.

With those back in, the cluster now seems to operate correctly again. I was getting a P0175 code for faulty trans input/output sensor, but I suspect that may have been from having the cluster wires disconnected. I cleared the codes and drove around, and all I'm getting now is the usual P0700 and P0753 I've had from the beginning.

I then tried unplugging the TCM per the other thread you posted and manually shifting through the gears. Evertyhing seems to work fine, that is, I only get 1st gear in 1-2, only 3rd in 3, and only 4th in D. Of course with the TCM unplugged I get P0700 and P1698 codes.

Now I'll try the voltage tests from the TCM connector as you recommend. I'll post those results.

#20

Thread Starter

CF Veteran

Joined: Jan 2014

Posts: 1,349

Likes: 287

From: District of Columbia

Year: 1998

Model: Cherokee (XJ)

Engine: 4.0

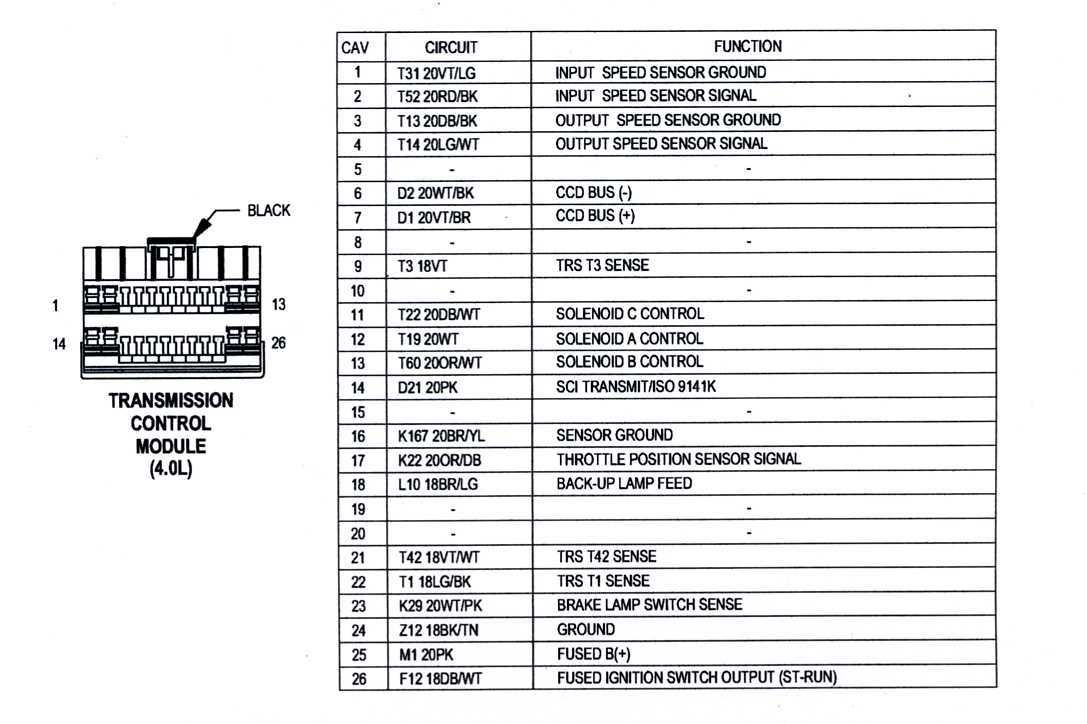

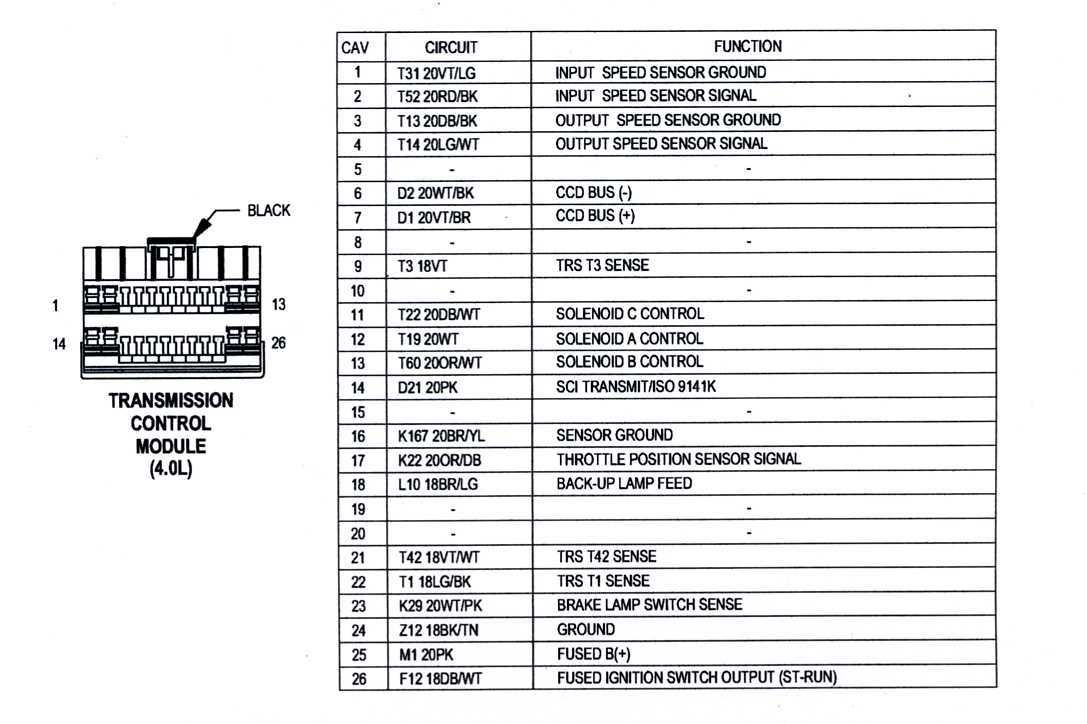

I ran some resistance tests as you recommended, and here's what I got. The numbers refer to this picture you posted in the other thread.

Between pin cavity 1 & 2: 716 ohms

Between 3 & 4: 692 ohms

Between 24 & 11: 15 ohms

Between 24 & 12: 31 ohms

Between 24 & 13: 15 ohms

The bolded part (between pin cavities 24 & 12) corresponds to solenoid A, which is responsible for the 1-2 and 3-4 shift according to your picture. This is consistent with what appears to be happening when I drive, as I only have gears 1 and 3 and no TC lockup. The resistance on the input and output speed sensors looks a little high, but it's a lot better than solenoid A. I did not test (yet) do the voltage checks.

What do you recommend at this point? I still need to pull the connector near the trans dipstick and check for a possible bad connection there. If that looks good, should I assume that solenoid A needs to be replaced? I seem to recall a thread around here somewhere showing how do do that. It seemed relatively straightforward.

Edit: I checked that connector near the dipstick and it looks clean and snug. Maybe a little terminal cleaner and dielectric grease wouldn't hurt.

Between pin cavity 1 & 2: 716 ohms

Between 3 & 4: 692 ohms

Between 24 & 11: 15 ohms

Between 24 & 12: 31 ohms

Between 24 & 13: 15 ohms

The bolded part (between pin cavities 24 & 12) corresponds to solenoid A, which is responsible for the 1-2 and 3-4 shift according to your picture. This is consistent with what appears to be happening when I drive, as I only have gears 1 and 3 and no TC lockup. The resistance on the input and output speed sensors looks a little high, but it's a lot better than solenoid A. I did not test (yet) do the voltage checks.

What do you recommend at this point? I still need to pull the connector near the trans dipstick and check for a possible bad connection there. If that looks good, should I assume that solenoid A needs to be replaced? I seem to recall a thread around here somewhere showing how do do that. It seemed relatively straightforward.

Edit: I checked that connector near the dipstick and it looks clean and snug. Maybe a little terminal cleaner and dielectric grease wouldn't hurt.

Last edited by IJM; 06-28-2014 at 12:28 AM.

#21

CF Veteran

Joined: Aug 2010

Posts: 8,357

Likes: 90

From: Canton, MI

Year: 1999

Model: Cherokee

Engine: 4.0

I ran some resistance tests as you recommended, and here's what I got. The numbers refer to this picture you posted in the other thread.

Between pin cavity 1 & 2: 716 ohms

Between 3 & 4: 692 ohms

Between 24 & 11: 15 ohms

Between 24 & 12: 31 ohms

Between 24 & 13: 15 ohms

The bolded part (between pin cavities 24 & 12) corresponds to solenoid A, which is responsible for the 1-2 and 3-4 shift according to your picture. This is consistent with what appears to be happening when I drive, as I only have gears 1 and 3 and no TC lockup. The resistance on the input and output speed sensors looks a little high, but it's a lot better than solenoid A. I did not test (yet) do the voltage checks.

What do you recommend at this point? I still need to pull the connector near the trans dipstick and check for a possible bad connection there. If that looks good, should I assume that solenoid A needs to be replaced? I seem to recall a thread around here somewhere showing how do do that. It seemed relatively straightforward.

Edit: I checked that connector near the dipstick and it looks clean and snug. Maybe a little terminal cleaner and dielectric grease wouldn't hurt.

Between pin cavity 1 & 2: 716 ohms

Between 3 & 4: 692 ohms

Between 24 & 11: 15 ohms

Between 24 & 12: 31 ohms

Between 24 & 13: 15 ohms

The bolded part (between pin cavities 24 & 12) corresponds to solenoid A, which is responsible for the 1-2 and 3-4 shift according to your picture. This is consistent with what appears to be happening when I drive, as I only have gears 1 and 3 and no TC lockup. The resistance on the input and output speed sensors looks a little high, but it's a lot better than solenoid A. I did not test (yet) do the voltage checks.

What do you recommend at this point? I still need to pull the connector near the trans dipstick and check for a possible bad connection there. If that looks good, should I assume that solenoid A needs to be replaced? I seem to recall a thread around here somewhere showing how do do that. It seemed relatively straightforward.

Edit: I checked that connector near the dipstick and it looks clean and snug. Maybe a little terminal cleaner and dielectric grease wouldn't hurt.

That connector you show in a previous post looks like a Diagnostic Splice Block. I see that thing in a '97 wiring diagram. I guess it was carried over to the '98 as well. The '99 doesn't use it.

That resistance reading for the Input Speed sensor is a bit high, which may be some corrosion in the speed sensor connector. The Input Speed Sensor is easy to get at so you may want to unplug the connector and inspect for corrosion an clean it out. While it's disconnected you can read the resistance of the sensor direct. Just go from pin to pin. It should be around 625-650 Ohms.

Concerning the solenoid A resistance, you may want to take a resistance reading from the connector at the dipstick to eliminate the possibility of a fault between the connector and the TCM. If the resistance is still high going from the connector to the solenoid I would say the solenoid is bad.

Here's a pinout of the connector at the dipstick. You are looking at the connector half that goes to the TCM so the other half that goes to the Solenoids is the mirror image. You'll have to take that into consideration when choosing the pin(s) to read. The wire colors do change from the TCM half to the Solenoids half. Read the Input and Output Speed Sensors while you're at it.

Note that there is no ground pin for the Solenoids. Use the engine as the ground for your meter.

.

#22

Thread Starter

CF Veteran

Joined: Jan 2014

Posts: 1,349

Likes: 287

From: District of Columbia

Year: 1998

Model: Cherokee (XJ)

Engine: 4.0

Gonna try all that in a minute. If I do end up needing to drop the pan to replace the solenoid, is it better to use a gasket or RTV?

#23

CF Veteran

Joined: Aug 2010

Posts: 8,357

Likes: 90

From: Canton, MI

Year: 1999

Model: Cherokee

Engine: 4.0

Be mindful that you may have a problem getting the dipstick tube apart (rust inside).

There's a tutorial floating around about using Toyota solenoids from Ebay.

#24

Thread Starter

CF Veteran

Joined: Jan 2014

Posts: 1,349

Likes: 287

From: District of Columbia

Year: 1998

Model: Cherokee (XJ)

Engine: 4.0

I picked up 3 new solenoids, a filter, and gasket from bulkpart.com. I figured I'd get all of them while I had it pulled apart. The dipstick tube was a PITA, by it's all cleaned up now with a new o-ring.

I'm hoping to get the work done tomorrow night. Should I use a thin coating of RTV on the gasket or just use it dry?

I'm hoping to get the work done tomorrow night. Should I use a thin coating of RTV on the gasket or just use it dry?

#25

CF Veteran

Joined: Aug 2010

Posts: 8,357

Likes: 90

From: Canton, MI

Year: 1999

Model: Cherokee

Engine: 4.0

I picked up 3 new solenoids, a filter, and gasket from bulkpart.com. I figured I'd get all of them while I had it pulled apart. The dipstick tube was a PITA, by it's all cleaned up now with a new o-ring.

I'm hoping to get the work done tomorrow night. Should I use a thin coating of RTV on the gasket or just use it dry?

I'm hoping to get the work done tomorrow night. Should I use a thin coating of RTV on the gasket or just use it dry?

The torque on the oil pan bolts is 53-70 inch pounds, the oil screen bolt is 80-96 inch pounds. As you can see there's not very much torque on these fasteners so don't over tighten them.

Before installing the oil pan test the resistance of the solenoids again to make sure all three are the proper resistance.

Good luck

.

#26

Thread Starter

CF Veteran

Joined: Jan 2014

Posts: 1,349

Likes: 287

From: District of Columbia

Year: 1998

Model: Cherokee (XJ)

Engine: 4.0

Success!

I put the new solenoids in and tested the resistance as the controller connector again. About 11 ohms on all 3 solenoids. Topped up the fluid and took it on a couple of drives around town. Everything works great now.

Thanks again for all the help on diagnosing the bad solenoids.

I put the new solenoids in and tested the resistance as the controller connector again. About 11 ohms on all 3 solenoids. Topped up the fluid and took it on a couple of drives around town. Everything works great now.

Thanks again for all the help on diagnosing the bad solenoids.

#27

CF Veteran

Joined: Aug 2010

Posts: 8,357

Likes: 90

From: Canton, MI

Year: 1999

Model: Cherokee

Engine: 4.0

Success!

I put the new solenoids in and tested the resistance as the controller connector again. About 11 ohms on all 3 solenoids. Topped up the fluid and took it on a couple of drives around town. Everything works great now.

Thanks again for all the help on diagnosing the bad solenoids.

I put the new solenoids in and tested the resistance as the controller connector again. About 11 ohms on all 3 solenoids. Topped up the fluid and took it on a couple of drives around town. Everything works great now.

Thanks again for all the help on diagnosing the bad solenoids.

Glad to see you out-foxed the stealership.

BTW: The next person that posts a complaint like you had you can give him/her the guidance required to fix it.

Cheers.

Thread

Thread Starter

Forum

Replies

Last Post

erupert66

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

11

06-07-2021 02:45 AM

DanO55

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

1

08-28-2015 08:16 PM

bfh_american

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

10

08-22-2015 01:15 PM

petejeep95

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

4

08-22-2015 12:39 PM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)