Little worried about compression test

#16

Member

Thread Starter

Join Date: Jan 2010

Location: omaha

Posts: 171

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1993

Model: Cherokee

Engine: 4.0 Liter H.O.

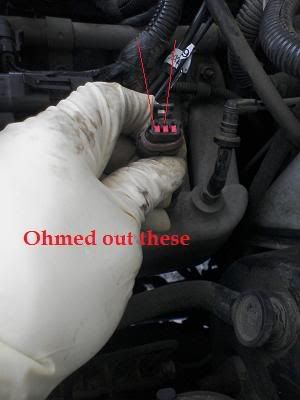

Sounds like exactly what happened to me when my Crankshaft Position Sensor crapped out. Check the resistance of it with an multimeter set to ohms. Here's a picture of the location

Now what you do is pop off the connector and measure the resistance between prongs B and C. There should be absolutely zero resistance.

Also, when mine blew out is also blew out the Camshaft Positioning Sensor (AKA a stator or pick-up coil) which is under the distributor cap. Here's an article to read about that.

http://www.lunghd.com/Tech_Articles/...lse_Stator.htm

A quick test to see if your CPS is possibly the culprit is to test the spark. Pop the plug wire coming from the coil off the top of the distributor and ground it out on a bare metal surface. Have a buddy crank it over and see if there is a bright blue spark. If there's no spark, or a dim spark, CPS is probably your culprit. Good luck with your Jeep.

Now what you do is pop off the connector and measure the resistance between prongs B and C. There should be absolutely zero resistance.

Also, when mine blew out is also blew out the Camshaft Positioning Sensor (AKA a stator or pick-up coil) which is under the distributor cap. Here's an article to read about that.

http://www.lunghd.com/Tech_Articles/...lse_Stator.htm

A quick test to see if your CPS is possibly the culprit is to test the spark. Pop the plug wire coming from the coil off the top of the distributor and ground it out on a bare metal surface. Have a buddy crank it over and see if there is a bright blue spark. If there's no spark, or a dim spark, CPS is probably your culprit. Good luck with your Jeep.

Sorry for poor quality of pics, was taken with my old camera phone, if you need better pics I can get the digital camera out.

Last edited by Dsandine; 02-20-2010 at 03:25 PM.

#17

CF Veteran

Join Date: Nov 2009

Location: New Jersey

Posts: 1,261

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1996

Model: Cherokee

Engine: 4.0 HO

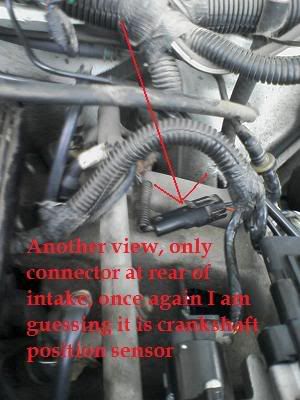

Second picture of what you ohm tested is correct. You want to test the unit itself located on the bellhousing, not the other connector. There should have been zero resistance. If there is zero resistance, chances are it's fine. If it even flickers between 0 and a decimal number, then it needs to be replaced. Also, I'd recommend testing it on all the ohm setting to make sure it's absolute zero. After testing the CPS again on all the settings, if it shows zero resistance again, then I'd look into the pickup coil, instead. Here's the article on that again http://www.lunghd.com/Tech_Articles/...lse_Stator.htm . Even though the article is about the Renix engines, it still informs you about the HO engine you have. If you're gonna replace it, pry up on the rubber bushing holding the connector and wiring into the distributor. While doing that, you also want to carefully pry the rest of it up. If you do it that way it shouldn't break. I broke mine just trying to pry up on the plastic of the pick-up coil. After that, I was irritated and a new one cost $40 and my distributor was already messed up because I stripped the threads that hold the cap on so I went to the JY and got one for free. Installed it and it started right up. If you decide to remove the distributor, make sure it goes back in the same way it came out. Note the way the flat piece on the bottom is facing when you pull it out. If your distributor is improperly "indexed", it will cause a no spark or faint spark condition. Let me know if you need any help and I'll try my best to help you out going by my experience with it. Good luck with your Jeep.

#18

Member

Thread Starter

Join Date: Jan 2010

Location: omaha

Posts: 171

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1993

Model: Cherokee

Engine: 4.0 Liter H.O.

upon further testing I figured that pin B is the ground, and I tested it and it is a good ground. I read this following post on a forum, and according to it there should be resistance between the b & c pins. I have checked with the sensor plugged in and not plugged in, and with pcm disconnected and not disconnected, and no matter what I have resistance, (over 1k) between pins b and c. But I have also read on two other forums there is not supposed to be resistance between b & c so I am very confused right now. Also I know pin b is black/blue and is ground, pin a is orange and is supposed to supple 5 volts to CPS, and there is a good five volts there, according to what I have read pin c is just for the signal from CPS to go to PCM. Well with key in run position I have 9 volts there, that's not turning over, or with engine running (because it won't run) and the 9 volts is definitely coming from pcm because when I unplug the CPS, the 9 volts is still present at connector that goes to pcm. I would expect the pcm to have no voltage there, I am guessing the CPS is a hall effect sender of some sort or send some kind of voltage or waveform to pcm, so I definitely do not think the pcm should be putting out 9 volts to pin c, which is the gray/black wire. Is my pcm shot and my CPS bad? or is my pcm just shot? Here is what I read that lead me to believe 9 volts coming out of pcm is bad.

"

sorry to say that I don't have a wiring or diag book for a 93(these things disappear over time)I have a 91 diag book and 96,that's the closest I can get.yes you should have 5 volts on one pin(reference voltage).ground on another and the third should not have anything as it is a signal wire to the pcm.now that being said if you have 9 volts on the signal return wire the jeep should never start and run!when you check the return wire for continuity the key should be off and both the crank sensor and pcm should be disconnected.here is some other info that may be of help.CRANKSHAFT POSITION SENSOR

The Powertrain Control Module (PCM) supplies 5 volts to the crankshaft position sensor on circuit K6. Circuit K6 connects to cavity A17 of the PCM.

The PCM receives the crankshaft position sensor signal on circuit K24. Circuit K24 connects to cavity A8 of the PCM.

The PCM provides a ground for the crankshaft position sensor (circuit K24) through circuit K4. Circuit K4 connects to cavity A4 of the PCM.

HELPFUL INFORMATION

* Circuit K6 splices to supply 5 volts to the camshaft position sensor.

Circuit K4 splices to supply ground for the signals from the following:

* Upstream and downstream heated oxygen sensor

* Camshaft position sensor

* Intake air temperature sensor

* Throttle position sensor

* Manifold absolute pressure sensor

* Engine coolant temperature sensor

* Vehicle speed sensor

To perform a complete test of this sensor and its circuitry, refer to the DRB scan tool. Also refer to the appropriate Powertrain Diagnostics Procedures manual. To test the sensor only, refer to the following:

The sensor is located on the transmission bellhousing at the left/rear side of the engine block Crankshaft Position Sensor - 2.5L 4-Cyl. Engine - Typical or Crankshaft Position Sensor - 4.0L 6-Cyl. Engine

1. Near the rear of the intake manifold, disconnect sensor pigtail harness connector from main wiring harness.

2. Place an ohmmeter across terminals B and C Crankshaft Position Sensor Connector Ohmmeter should be set to 1K-to-10K scale for this test. The meter reading should be open (no resistance) Replace sensor if a low resistance is indicated.

tipicaly if you have 5 volts a ground with 8 ohms or less and a return wire that is 1 ohm or less it either needs a pcm or a sensor.I belive the bolt size is a 10 or 13mm. sorry to say I dont have one to check and the service manuals do not give that kind of info.let me know what eles I can do.

Read more: http://www.justanswer.com/questions/...#ixzz0g7CXgg7R"

I am lost, any suggestions?

"

sorry to say that I don't have a wiring or diag book for a 93(these things disappear over time)I have a 91 diag book and 96,that's the closest I can get.yes you should have 5 volts on one pin(reference voltage).ground on another and the third should not have anything as it is a signal wire to the pcm.now that being said if you have 9 volts on the signal return wire the jeep should never start and run!when you check the return wire for continuity the key should be off and both the crank sensor and pcm should be disconnected.here is some other info that may be of help.CRANKSHAFT POSITION SENSOR

The Powertrain Control Module (PCM) supplies 5 volts to the crankshaft position sensor on circuit K6. Circuit K6 connects to cavity A17 of the PCM.

The PCM receives the crankshaft position sensor signal on circuit K24. Circuit K24 connects to cavity A8 of the PCM.

The PCM provides a ground for the crankshaft position sensor (circuit K24) through circuit K4. Circuit K4 connects to cavity A4 of the PCM.

HELPFUL INFORMATION

* Circuit K6 splices to supply 5 volts to the camshaft position sensor.

Circuit K4 splices to supply ground for the signals from the following:

* Upstream and downstream heated oxygen sensor

* Camshaft position sensor

* Intake air temperature sensor

* Throttle position sensor

* Manifold absolute pressure sensor

* Engine coolant temperature sensor

* Vehicle speed sensor

To perform a complete test of this sensor and its circuitry, refer to the DRB scan tool. Also refer to the appropriate Powertrain Diagnostics Procedures manual. To test the sensor only, refer to the following:

The sensor is located on the transmission bellhousing at the left/rear side of the engine block Crankshaft Position Sensor - 2.5L 4-Cyl. Engine - Typical or Crankshaft Position Sensor - 4.0L 6-Cyl. Engine

1. Near the rear of the intake manifold, disconnect sensor pigtail harness connector from main wiring harness.

2. Place an ohmmeter across terminals B and C Crankshaft Position Sensor Connector Ohmmeter should be set to 1K-to-10K scale for this test. The meter reading should be open (no resistance) Replace sensor if a low resistance is indicated.

tipicaly if you have 5 volts a ground with 8 ohms or less and a return wire that is 1 ohm or less it either needs a pcm or a sensor.I belive the bolt size is a 10 or 13mm. sorry to say I dont have one to check and the service manuals do not give that kind of info.let me know what eles I can do.

Read more: http://www.justanswer.com/questions/...#ixzz0g7CXgg7R"

I am lost, any suggestions?

#19

Member

Thread Starter

Join Date: Jan 2010

Location: omaha

Posts: 171

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1993

Model: Cherokee

Engine: 4.0 Liter H.O.

Second picture of what you ohm tested is correct. You want to test the unit itself located on the bellhousing, not the other connector. There should have been zero resistance. If there is zero resistance, chances are it's fine. If it even flickers between 0 and a decimal number, then it needs to be replaced. Also, I'd recommend testing it on all the ohm setting to make sure it's absolute zero. After testing the CPS again on all the settings, if it shows zero resistance again, then I'd look into the pickup coil, instead. Here's the article on that again http://www.lunghd.com/Tech_Articles/...lse_Stator.htm . Even though the article is about the Renix engines, it still informs you about the HO engine you have. If you're gonna replace it, pry up on the rubber bushing holding the connector and wiring into the distributor. While doing that, you also want to carefully pry the rest of it up. If you do it that way it shouldn't break. I broke mine just trying to pry up on the plastic of the pick-up coil. After that, I was irritated and a new one cost $40 and my distributor was already messed up because I stripped the threads that hold the cap on so I went to the JY and got one for free. Installed it and it started right up. If you decide to remove the distributor, make sure it goes back in the same way it came out. Note the way the flat piece on the bottom is facing when you pull it out. If your distributor is improperly "indexed", it will cause a no spark or faint spark condition. Let me know if you need any help and I'll try my best to help you out going by my experience with it. Good luck with your Jeep.

Its not reading absolute zero ohms, its reading over 1k of resistance when it is unplugged and and about 2k of resistance when it is plugged in. I have also checked further down the wire towards the transmission to make sure it wasn't connector and it still reads over 1k of resistance.

#20

CF Veteran

Join Date: Nov 2009

Location: New Jersey

Posts: 1,261

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1996

Model: Cherokee

Engine: 4.0 HO

If there's any resistance, best bet is to replace it. I believe on the RENIX engines there is supposed to be a small amount of resistance. You have a High Output, so there should be zero resistance between pins B and C. The CPS always craps out on the Cherokees so even if it turns out not to be the problem, it's a good idea to replace it anyway. If the CPS were to crap out in the woods, it wouldn't be too fun. Honestly, if I were you, I would change it. You'll need a whole bunch of extensions, a universal joint, and a buddy to help you out. Someone has to crawl under the Jeep and snake the socket up to the CPS and the other guy has to guide the socket onto the bolt. It's the easiest way to do it. Also, a good idea is to put a little piece of tape on the universal so it isn't too floppy while your trying to get it on there. I did it in the freezing cold, laying down in the snow, and it took about 30 minutes after figuring out the best way was to do it from underneath.

#21

Member

Thread Starter

Join Date: Jan 2010

Location: omaha

Posts: 171

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1993

Model: Cherokee

Engine: 4.0 Liter H.O.

So I just did the ignition off on off on offf on to see if there were any codes, and I noticed I don't have any warning lights at all, no check engine light, also my gauges seem to be not working, like when I turn key to run temp gauge doesn't register were it should and neither does voltage gauge, no brake light on warning console or seatbelt light.

Anyone know how to test if a pcm is bad, and if it is bad, does anyone know what year I can try to snag one from, I have a 93- so does it have to be like from 91-93, and I assume it has to be an ecm from a manual, or will an auto tranny one work.

Also I guess it could just be a shorted sensor dragging everything down, I will try pulling sensors tomorrow. (In the snow, yuck)

Also I am almost 100% sure there should be resistance between pins b & c. The crankshaft position sensor has a three wire circuit, one wire is the ground, one wire is the 8 volt supply, which definitely shouldn't be shorted to ground wire or the third wire, which is the return line for the crankshaft position sensor, which is a hall effect waveform generator, which sends a square wave to the pcm which uses that for timing for important things (firing injectors is one of them) so that wire should absolutely not be shorted (read 0 ohms) to "pin b" or the ground wire, it should not read 0 ohms to any wire in that circuit or the square wave will never reach the pcm and the motor won't work. Basically, none of those three wires should read 0 ohms to any other of the three wires (or pins) or it is impossible for the circuit to work and the square wave will never reach the pcm causing engine not to rum, it seems like Eric Giordano (the guy who takes credit for that website) was mistaken in his information (which is not a knock to him, we all have made mistakes in our time) but to reiterate it is impossible for that sensor to work properly if any wire in circuit (or pin) reads zero ohms in relation to any other wire (or pin) in that circuit, unless the PCM schematic I have in the 93 fsm is wrong, which it very well could be, but even if it was I would still suspect that the CKS (crankshaft position sensor) is nothing more than a hall effect generator used for timing, and no matter what the only thing that should read o ohms is when you ground the ground wire in circuit to a good chassis ground or negative terminal of battery.

Anyone know how to test if a pcm is bad, and if it is bad, does anyone know what year I can try to snag one from, I have a 93- so does it have to be like from 91-93, and I assume it has to be an ecm from a manual, or will an auto tranny one work.

Also I guess it could just be a shorted sensor dragging everything down, I will try pulling sensors tomorrow. (In the snow, yuck)

Also I am almost 100% sure there should be resistance between pins b & c. The crankshaft position sensor has a three wire circuit, one wire is the ground, one wire is the 8 volt supply, which definitely shouldn't be shorted to ground wire or the third wire, which is the return line for the crankshaft position sensor, which is a hall effect waveform generator, which sends a square wave to the pcm which uses that for timing for important things (firing injectors is one of them) so that wire should absolutely not be shorted (read 0 ohms) to "pin b" or the ground wire, it should not read 0 ohms to any wire in that circuit or the square wave will never reach the pcm and the motor won't work. Basically, none of those three wires should read 0 ohms to any other of the three wires (or pins) or it is impossible for the circuit to work and the square wave will never reach the pcm causing engine not to rum, it seems like Eric Giordano (the guy who takes credit for that website) was mistaken in his information (which is not a knock to him, we all have made mistakes in our time) but to reiterate it is impossible for that sensor to work properly if any wire in circuit (or pin) reads zero ohms in relation to any other wire (or pin) in that circuit, unless the PCM schematic I have in the 93 fsm is wrong, which it very well could be, but even if it was I would still suspect that the CKS (crankshaft position sensor) is nothing more than a hall effect generator used for timing, and no matter what the only thing that should read o ohms is when you ground the ground wire in circuit to a good chassis ground or negative terminal of battery.

Last edited by Dsandine; 02-21-2010 at 02:11 AM.

Thread

Thread Starter

Forum

Replies

Last Post

cpnwrench

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

14

05-05-2024 12:21 PM

Raney120

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

22

10-16-2015 11:27 AM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)