No bus w/air bag after heater core replacement.

#16

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 36

Likes: 1

From: Nebraska

Year: 2001

Model: Cherokee

Engine: 4.0l

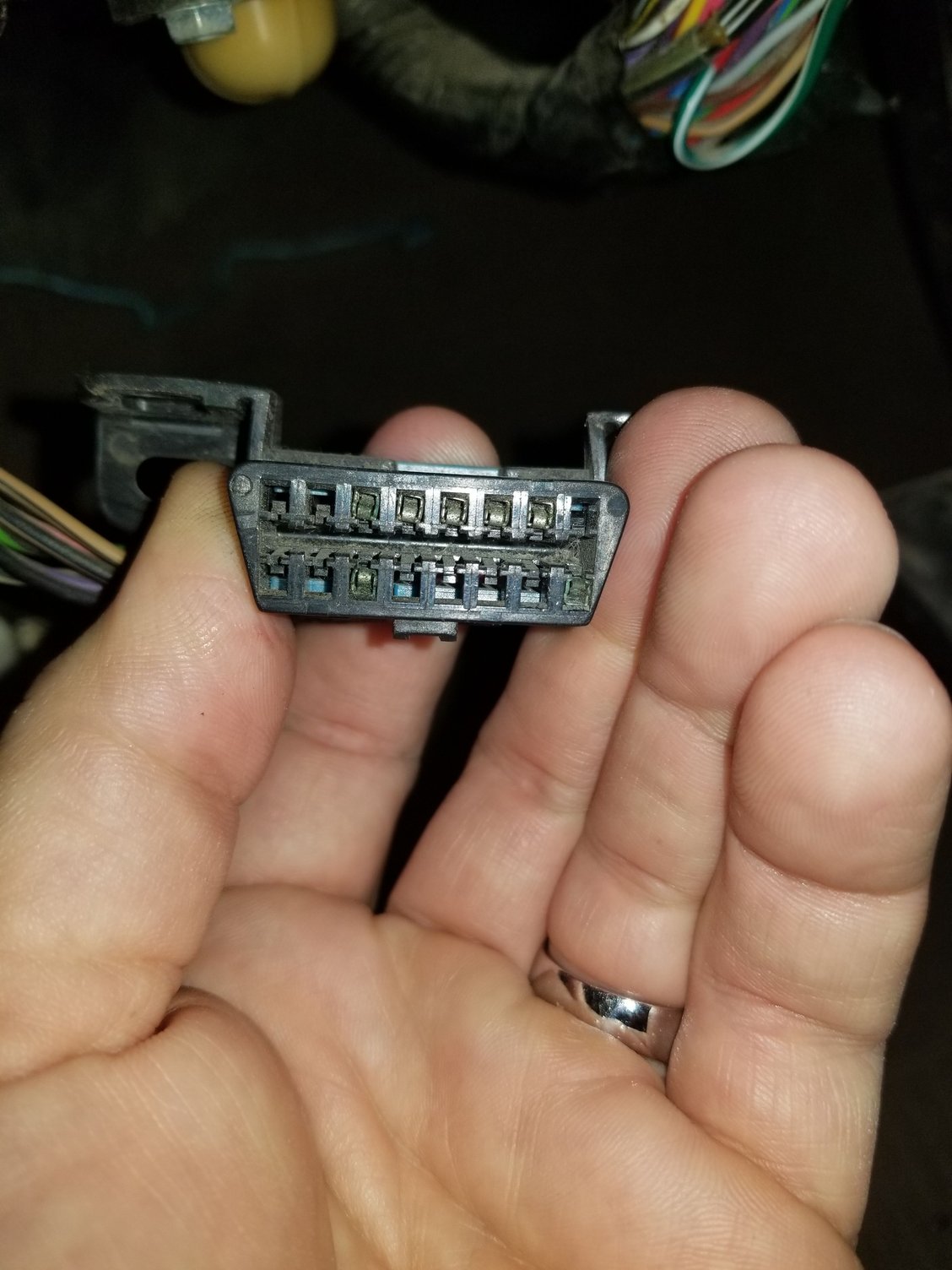

Mine skips 2 and starts at 3 while maintaining 4,5,6,7. On the bottom row, mine only uses 11 and 16. Some diagrams I found online refer to this as ccd bus. If this is the same, I will check it tonight.

#17

Banned

Joined: Feb 2019

Posts: 1,359

Likes: 169

From: NC

Year: 2004

Model: Grand Cherokee (WJ)

Engine: 4.0

Oh, sorry.. I was wrong, and you are right it is a CCD bus on those years 2001 XJ models, and has a different connector and pins. There are several types of different CCD or PCI bus types used by Chrysler. They change their daisy chains with how the modules are linked together at their central hubs vs at the BCM vs some other things about the routing of things.. Those things are important when trying to associate a failed part to a hub vs a neighboring module via the different possible paths etc.. The premise is still the same though.

The CCD bus has its communications wire on the #3 pin. That is where to check vs the #2 pin how it is on a WJs PCI bus system. I apologize for the confusion.

It is still the same basics though. The bus wire is biased towards 2.5 VOLTS.

I simplified it above for the normal fluctuating voltage reading to be between 0.5V - 2.5 VOLTS. To be 100% accurate it goes more like this... A consistently fluctuating reading seen as staying above 2.5V constant is an abnormal voltage. For example, if you see 0.9V fluctuating to 1.6V and back.. Then, it shoots up to 5.8V for a second back down to 0.7V fluctuating to 2.5V, and then back to around 4V... and back to 1.6V etc... That is a normal fluctuating voltage.... Because it is not consistently fluctuating above 2.5 VOLTS. Does that make sense?

It is a square wave 0.5 VOLTS to 7 VOLTS... Anytime if you see a reading above 7 VOLTS something is wrong, as that is abnormal. It can go up to 5V, 6V, up to 7 VOLTS briefly for a period, and this is normal though.

But, if you see consistently fluctuating voltages that are staying greater than 2.5 VOLTS.... That is an abnormal reading.

It is biased to 2.5 VOLTS.. and it ussually will normally stay fluctuating at around 1V - 2 VOLTS.

The CCD bus has its communications wire on the #3 pin. That is where to check vs the #2 pin how it is on a WJs PCI bus system. I apologize for the confusion.

It is still the same basics though. The bus wire is biased towards 2.5 VOLTS.

I simplified it above for the normal fluctuating voltage reading to be between 0.5V - 2.5 VOLTS. To be 100% accurate it goes more like this... A consistently fluctuating reading seen as staying above 2.5V constant is an abnormal voltage. For example, if you see 0.9V fluctuating to 1.6V and back.. Then, it shoots up to 5.8V for a second back down to 0.7V fluctuating to 2.5V, and then back to around 4V... and back to 1.6V etc... That is a normal fluctuating voltage.... Because it is not consistently fluctuating above 2.5 VOLTS. Does that make sense?

It is a square wave 0.5 VOLTS to 7 VOLTS... Anytime if you see a reading above 7 VOLTS something is wrong, as that is abnormal. It can go up to 5V, 6V, up to 7 VOLTS briefly for a period, and this is normal though.

But, if you see consistently fluctuating voltages that are staying greater than 2.5 VOLTS.... That is an abnormal reading.

It is biased to 2.5 VOLTS.. and it ussually will normally stay fluctuating at around 1V - 2 VOLTS.

Last edited by Noah911; 12-02-2019 at 09:03 AM.

The following users liked this post:

duder1982 (12-02-2019)

#19

Something similar happened to me, try disconnecting the airbag control module under the dash in the driver's side for a few minutes and plug it back in, make sure You disconnect the battery before You try it.

The following users liked this post:

duder1982 (12-02-2019)

#20

Banned

Joined: Feb 2019

Posts: 1,359

Likes: 169

From: NC

Year: 2004

Model: Grand Cherokee (WJ)

Engine: 4.0

I posted the XJ diagram above as I was walking out the door this morning. After actually looking at it, I realized there are some pretty significant differences between the two; the PCI and the CCD bus systems.. I am familiar with the PCI bus. Although, I am honestly not really all that familiar with the CCD bus system.

I briefly read a few things from officially sourced documents. One of the things I read was from Chryslers, The Performance Institute training manual. If you type that into your web browser along with the words - CAN bus (Controller Area Network, bus) you could pull it from the Web yourself, to find and read some of it too. It is not exactly the easiest read though.

One important thing I did not realize about the CCD bus, is that it is a twisted two-wire communications system vs the WJs one-wire communications PCI bus system. This causes some differences.. For one, the PCI system in a WJ can transmit electronic signals backwards and forwards. The termination resistor(s) are also a big difference. The CCD bus allows voltage drop with these in order to maintain a difference of about 0.02 VOLTS between the (+) and (-) dual wire CCD bus circuits, in order to keep the base voltage biased at 2.5V. This changes a few things. For example, if the BUS(+) sits at 2.8V, then the BUS(-) will be 2.2V in order for a logic zero. External resistors will bias the bus lines... blah blah blah!

You have to get two readings. The BUS (+) and BUS(-) voltages from pins #3 and #11. Especially, if one or the other is showing as a very abnormal reading. For instance, if there is an open or short on BUS(+) it may read at 0.0V while BUS(-) on the other pin will read at 5V.. as an example.

The airbag light/module is used as an indicator. It is set-up like it is purposely as an indicator to aid in pointing out when there is a problem in the bus. That doesn't mean something is not wrong with the airbag module either though. So is the cluster gauges how they are not working.. as well as the compass. Those three things are all used as additional indicators for when problems are occuring in the bus...

(edited to add):

One easy thing to try.. Disconnecting your battery may reboot the system, to re-set something that is presenting as faulty right now to make it go back to normal.

I briefly read a few things from officially sourced documents. One of the things I read was from Chryslers, The Performance Institute training manual. If you type that into your web browser along with the words - CAN bus (Controller Area Network, bus) you could pull it from the Web yourself, to find and read some of it too. It is not exactly the easiest read though.

One important thing I did not realize about the CCD bus, is that it is a twisted two-wire communications system vs the WJs one-wire communications PCI bus system. This causes some differences.. For one, the PCI system in a WJ can transmit electronic signals backwards and forwards. The termination resistor(s) are also a big difference. The CCD bus allows voltage drop with these in order to maintain a difference of about 0.02 VOLTS between the (+) and (-) dual wire CCD bus circuits, in order to keep the base voltage biased at 2.5V. This changes a few things. For example, if the BUS(+) sits at 2.8V, then the BUS(-) will be 2.2V in order for a logic zero. External resistors will bias the bus lines... blah blah blah!

You have to get two readings. The BUS (+) and BUS(-) voltages from pins #3 and #11. Especially, if one or the other is showing as a very abnormal reading. For instance, if there is an open or short on BUS(+) it may read at 0.0V while BUS(-) on the other pin will read at 5V.. as an example.

The airbag light/module is used as an indicator. It is set-up like it is purposely as an indicator to aid in pointing out when there is a problem in the bus. That doesn't mean something is not wrong with the airbag module either though. So is the cluster gauges how they are not working.. as well as the compass. Those three things are all used as additional indicators for when problems are occuring in the bus...

(edited to add):

One easy thing to try.. Disconnecting your battery may reboot the system, to re-set something that is presenting as faulty right now to make it go back to normal.

Last edited by Noah911; 12-02-2019 at 06:17 PM.

#21

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 36

Likes: 1

From: Nebraska

Year: 2001

Model: Cherokee

Engine: 4.0l

The airbag light/module is used as an indicator. It is set-up like it is purposely as an indicator to aid in pointing out when there is a problem in the bus. That doesn't mean something is not wrong with the airbag module either though. So is the cluster gauges how they are not working.. as well as the compass. Those three things are all used as additional indicators for when problems are occuring in the bus...

(edited to add):

One easy thing to try.. Disconnecting your battery may reboot the system, to re-set something that is presenting as faulty right now to make it go back to normal.

Battery has been disconnected multiple times. I would think whatever needed to be reset has been.

#22

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 36

Likes: 1

From: Nebraska

Year: 2001

Model: Cherokee

Engine: 4.0l

Then again, I don't see why the compass circuit would have anything to do with my issue as I don't have a compass. It does make since as it's all tied to that same cluster and air bag circuit.

#23

Banned

Joined: Feb 2019

Posts: 1,359

Likes: 169

From: NC

Year: 2004

Model: Grand Cherokee (WJ)

Engine: 4.0

Question is, is that my issue or a failed component. Theres a few places I need to re check. The air bag wires and gage cluster appear to check out. What about this compass wiring?

Battery has been disconnected multiple times. I would think whatever needed to be reset has been.

Battery has been disconnected multiple times. I would think whatever needed to be reset has been.

With your question.. I do not know what you are asking? You said - "is that my issue, or a failed component"

What is "that"? You do not have a failed component. You have a failed system. The BUS communications system.

If you do not have a compass.. (See below)

I think we have a miscommunication? With what I mentioned about the airbag light, the cluster gauges going out, and the compass not working. These three things how I was mentioning them have nothing to do with your Jeeps own specific problem. These three things; the way I understand it, they were built into the design of the BUS system to automatically stop working whenever there is any type of problem going on with the BUS. The Chrysler engineers did this on purpose as sort of a back-up to a back-up.. to signal and indicate to mechanics and auto technicians whenever they are working on these vehicles, so that they would know to be sure and recognize with a very high level of certainty that there is indeed an issue occuring here at, and on the BUS communications system (one of the most critically important systems on your Jeep). When the BUS goes down.. it is possible for communications to go haywire throughout any, or all of the systems. The 'no bus' message showing up on the odometer may not even be able to happen sometimes to let you know because of how sick the Jeep may become when it has an unhealthy BUS.

If you did have a compass it most likely probably would not be working either.

Last edited by Noah911; 12-03-2019 at 01:48 AM.

#24

Banned

Joined: Feb 2019

Posts: 1,359

Likes: 169

From: NC

Year: 2004

Model: Grand Cherokee (WJ)

Engine: 4.0

Checking the BUS wires voltages at the DLC #3 and #11 pins has the ability to rule three things out immediately; an open, short to ground, or a short to voltage. If you don't at least rule these three lesser likely possible reasons out somehow? You could be looking for a long time...

You can check the BUS wires anywhere you want. The BUS wires run front to back, side to side, and to every component.. So, you have a lot of choices! It is just easier to use the pins at the DLC. The same location where you would use a high-end DRBIII scanner tool. Unless, you know how to correctly use, and you have access to use a DRBIII scanner? I would reccomend to use the DRBIII scanner if you do.. An OBDII scanner will not work so well for this type of issue.

The BUS links together everything! All components, modules, sensors, every wire... A BUS problem can literally be anything.

You can check the BUS wires anywhere you want. The BUS wires run front to back, side to side, and to every component.. So, you have a lot of choices! It is just easier to use the pins at the DLC. The same location where you would use a high-end DRBIII scanner tool. Unless, you know how to correctly use, and you have access to use a DRBIII scanner? I would reccomend to use the DRBIII scanner if you do.. An OBDII scanner will not work so well for this type of issue.

The BUS links together everything! All components, modules, sensors, every wire... A BUS problem can literally be anything.

#25

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 36

Likes: 1

From: Nebraska

Year: 2001

Model: Cherokee

Engine: 4.0l

Ok, now I understand what you mean about the 3 components. It's not that one of those failed and now I have a no bus code. But that the bus failed and now I dont have those 3 components as an Indicator that the bus has failed. I do understand a little about can bus as heavy equipment uses it as well. However, I usually had either proper testing equipment or a couple of simple steps to take to identify the issues. Most the the harness I work with are short distance between check points, so as long as I had a schematic, I could easily check and make sure it's not a wire issue. It seems you are using the DLP in this same manner. I got a little carried away last night checking wires once I found a schematic, also because part of me believes that I must have damaged or disconnected one somewhere along the chain. I will check voltage tonight and see what we have.

Thanks for all your help on this, I've been a little rusty as i haven't been in this field for a while.

Thanks for all your help on this, I've been a little rusty as i haven't been in this field for a while.

#26

Banned

Joined: Feb 2019

Posts: 1,359

Likes: 169

From: NC

Year: 2004

Model: Grand Cherokee (WJ)

Engine: 4.0

It really seems like it should be related to the recent work or something to me too (it just seems that way in my mind though), with how the problem came about for you. Honestly, seems like it is a logical thought process, you know? If it were me, I would have wanted to believe that when trying to fix it... I probably would have forced myself to look there at first, even though I know that this is not exactly how the system works.

It is all about correctly using a DRBIII to look for the problem. Or, to simulating using one of those scanners by checking for the voltage on the BUS wires with a voltmeter. These are really the only ways providing evidence.. to look for, and to see what the system can tell you.

In this case.. I hope something is wrong when you check to see, and there is a problem on your BUS wires for you.

It is all about correctly using a DRBIII to look for the problem. Or, to simulating using one of those scanners by checking for the voltage on the BUS wires with a voltmeter. These are really the only ways providing evidence.. to look for, and to see what the system can tell you.

In this case.. I hope something is wrong when you check to see, and there is a problem on your BUS wires for you.

Last edited by Noah911; 12-03-2019 at 08:01 AM.

#28

Banned

Joined: Feb 2019

Posts: 1,359

Likes: 169

From: NC

Year: 2004

Model: Grand Cherokee (WJ)

Engine: 4.0

That is the correct way. (Not the first pin #3 to pin #11 way though). How you did it using ground to pin, when you got the 80 milivolts readings is correct. The Jeep was on and running right? It sounds like it probably was with getting the 80 milivolts, since when it sleeps it is less than that (around 20 milivolts). It is supposed to be on and running when obtaining readings though, and that would be the correct way.

Those readings are very far outside of normal parameters. An extreme low-normal voltage reading on either of these pins is when it gets near to 1.8 VOLTS. You are seeing 0.08 VOLTS! Is that the highest value the readings got up to as they were fluctuating (it sounds like it was..but to be sure)?

Based off the voltage reading you are seeing, you have ruled out three things. It is not open for sure. It is also definitely not shorted to voltage (which is a VERY good thing!). And it most likely does not sound like it is shorted to ground with having a 0.08 VOLTS reading. Plus, the two readings are not contrary, or showing an inverse order how an open or short to ground would normally be either.

This means - it sounds like it is probably a module that has a fault. The modules communicate in binary code by way of microvolts. A very very small voltage is a [0]. A slightly higher, but still very very small voltage is a [1] as their language. They send thousands of these bits as bytes, talking to each other all of the time. The modules ignore messages that are not meant for them to read. It sounds like one of the modules has a fault, and this is causing a disruption to occur in communication between all of the modules.

If you had an open, or short to ground.. you would have needed to disconnect your battery negative, and be looking to find the problem from the opposite direction in Ohms.

If you had a short to voltage.. you may end up having to trace the entire BUS wire throughout the whole Jeep.

With the readings you are getting.. you are supposed to begin unplugging individual modules one at a time. While at the same time watching to see what happens on the voltmeter for readings at both the #3 and #11 pins. You watch to see when the voltage returns to a normal within parameters reading how it should be. The CCD Bus parameter is normal between 1.8 VOLTS minimum and fluctuating up to 2.5 VOLTS as the maximum allowable voltage reading on the BUS wires. (Possibly up to 2.8 VOLTS for maximum may not cause problems, since it is possible for the system the way it is set-up to still compensate).

The first most likely modules to check are the ones in that diagram above, and then all of the rest of them.. One by one, until you find the module causing the problem. You are supposed to keep all of the modules unplugged as you go along, until you find the faulty module. Then, plug all of the other modules back in again... After this, you re-create the issue by finally re-plugging the problem module back in (last).. to see it make the problem happen. The way in how you do this is important to follow. Otherwise, the problem module(s) may fool you into believing that a normal healthy module actually has a fault, when it does not.

(edited):

Do not pull your gauge cluster because it supplies the termination resistance. It is backed up by the PCM, but still... This is one of the last modules to pull.

Those readings are very far outside of normal parameters. An extreme low-normal voltage reading on either of these pins is when it gets near to 1.8 VOLTS. You are seeing 0.08 VOLTS! Is that the highest value the readings got up to as they were fluctuating (it sounds like it was..but to be sure)?

Based off the voltage reading you are seeing, you have ruled out three things. It is not open for sure. It is also definitely not shorted to voltage (which is a VERY good thing!). And it most likely does not sound like it is shorted to ground with having a 0.08 VOLTS reading. Plus, the two readings are not contrary, or showing an inverse order how an open or short to ground would normally be either.

This means - it sounds like it is probably a module that has a fault. The modules communicate in binary code by way of microvolts. A very very small voltage is a [0]. A slightly higher, but still very very small voltage is a [1] as their language. They send thousands of these bits as bytes, talking to each other all of the time. The modules ignore messages that are not meant for them to read. It sounds like one of the modules has a fault, and this is causing a disruption to occur in communication between all of the modules.

If you had an open, or short to ground.. you would have needed to disconnect your battery negative, and be looking to find the problem from the opposite direction in Ohms.

If you had a short to voltage.. you may end up having to trace the entire BUS wire throughout the whole Jeep.

With the readings you are getting.. you are supposed to begin unplugging individual modules one at a time. While at the same time watching to see what happens on the voltmeter for readings at both the #3 and #11 pins. You watch to see when the voltage returns to a normal within parameters reading how it should be. The CCD Bus parameter is normal between 1.8 VOLTS minimum and fluctuating up to 2.5 VOLTS as the maximum allowable voltage reading on the BUS wires. (Possibly up to 2.8 VOLTS for maximum may not cause problems, since it is possible for the system the way it is set-up to still compensate).

The first most likely modules to check are the ones in that diagram above, and then all of the rest of them.. One by one, until you find the module causing the problem. You are supposed to keep all of the modules unplugged as you go along, until you find the faulty module. Then, plug all of the other modules back in again... After this, you re-create the issue by finally re-plugging the problem module back in (last).. to see it make the problem happen. The way in how you do this is important to follow. Otherwise, the problem module(s) may fool you into believing that a normal healthy module actually has a fault, when it does not.

(edited):

Do not pull your gauge cluster because it supplies the termination resistance. It is backed up by the PCM, but still... This is one of the last modules to pull.

Last edited by Noah911; 12-04-2019 at 02:16 AM.

The following users liked this post:

duder1982 (12-04-2019)

#29

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 36

Likes: 1

From: Nebraska

Year: 2001

Model: Cherokee

Engine: 4.0l

It was getting late for me when I wrote my last message and one thing that I wasn't certain on was pin 11 which is bus - voltage. When checking this, should my negative probe still go to chassis ground or should it go to pin 11 with the positive going to b+( in this case pin 16). If the negative probe is supposed to go to the bus - and positive probe to b+, then I get a 12 volt reading. If this voltage check method is correct, then this tells me my bus - is shorted to ground.

Ok, after reading up some more. Should I be referring to these as Can bus hi and can bus low? If this is correct, according to troubleshooting these, I should always have the negative to chassis ground. That being said, can bus low to ground is the se as can bus hi. Which seems to hold around .05 volts.

If all that is correct, it's time to start unplugging modules. If there is an aftermarket remote start (assuming its was installed correctly, it has worked for several years without issues), should it be treated as an OEM remote start module?

Ok, after reading up some more. Should I be referring to these as Can bus hi and can bus low? If this is correct, according to troubleshooting these, I should always have the negative to chassis ground. That being said, can bus low to ground is the se as can bus hi. Which seems to hold around .05 volts.

If all that is correct, it's time to start unplugging modules. If there is an aftermarket remote start (assuming its was installed correctly, it has worked for several years without issues), should it be treated as an OEM remote start module?

Last edited by duder1982; 12-04-2019 at 09:38 PM.

#30

Yes, that is what to do...somewhere I have seen a list of all the modules to pull and the the order to do it, while checking voltage...possibly even in the FSM ?