Possible PCM issue.

#16

Thread Starter

Member

Joined: Dec 2014

Posts: 167

Likes: 0

From: Ct

Year: 2004

Model: Grand Cherokee

Engine: 4.0

Bad news...I checked the entire harness and bought a new battery along with the PCM and was good for a day and a half.

Im really stumped now. A friend of mine that is a mechanic says its possible that the coolant temp sensor is bad and is causing it to dump more fuel than it needs to on start up, but again Im still not getting any codes. If anyone has any input it will be appreciated. Thank you

If anyone has any input it will be appreciated. Thank you

Im really stumped now. A friend of mine that is a mechanic says its possible that the coolant temp sensor is bad and is causing it to dump more fuel than it needs to on start up, but again Im still not getting any codes.

If anyone has any input it will be appreciated. Thank you

If anyone has any input it will be appreciated. Thank you

#17

If it's a wiring/connector issue you could replace a bunch of parts and still not fix it. I wouldn't replace anything especially the PCM unless I saw codes (like PO600-606) pointing to a problem with a circuit. Is there a reason you didn't want to post this in the Grand Cherokee section?

#19

#20

Bad news...I checked the entire harness and bought a new battery along with the PCM and was good for a day and a half.

Im really stumped now. A friend of mine that is a mechanic says its possible that the coolant temp sensor is bad and is causing it to dump more fuel than it needs to on start up, but again Im still not getting any codes. If anyone has any input it will be appreciated. Thank you

If anyone has any input it will be appreciated. Thank you

Im really stumped now. A friend of mine that is a mechanic says its possible that the coolant temp sensor is bad and is causing it to dump more fuel than it needs to on start up, but again Im still not getting any codes.

If anyone has any input it will be appreciated. Thank you

If anyone has any input it will be appreciated. Thank youLast edited by Turbo X_J; 11-13-2017 at 12:43 AM.

#22

Thread Starter

Member

Joined: Dec 2014

Posts: 167

Likes: 0

From: Ct

Year: 2004

Model: Grand Cherokee

Engine: 4.0

If it's a wiring/connector issue you could replace a bunch of parts and still not fix it. I wouldn't replace anything especially the PCM unless I saw codes (like PO600-606) pointing to a problem with a circuit. Is there a reason you didn't want to post this in the Grand Cherokee section?

#23

The PCM losing memory and now the radio losing its presets, to me, sounds like a flaky connection to me. Loss or power, obviously. The PCM and radio both need the battery to remain 'active' while the key is off, and both are having trouble with that so i have to ask, could it be a flaky connection to the battery?

#24

Thread Starter

Member

Joined: Dec 2014

Posts: 167

Likes: 0

From: Ct

Year: 2004

Model: Grand Cherokee

Engine: 4.0

Another weird thing I noticed every first start up after I disconnect the battery it starts perfect. But everytime after it needs the fuel pedal. Something resetting?

#25

This most likely isn't your issue, unless you having a problem with your fuel gauge. I once had problems with the XJ when the engine all of sudden began stopping for no reason, difficult to idle and difficult to start, to would not start.

I went over most everything and could not find the cause of the problem. So I kept driving a couple of weeks of intermittent hard starting, stalling, stopping, etc. (sometimes there wasn't any problems, everything was operating normally and then problems would start again for no apparent reason)

I then remembered that my fuel gauge was also sometimes behaving strangely not always providing the correct fuel gauge readings, would begin to fluctuate, etc.

So I pulled the gas tank and replaced the fuel sending unit as this was likely the problem with the fuel gauge. Once removed I tested to make certain the fuel ga sending unit was faulty as sometimes it's a problem with the wiring and connectors to the fuel pump assembly.

On later model XJ's such as the 98, the fuel gauge sending unit works by sending information directly to the PCM of which controls the fuel gauge, however this information is also used for other things such as idle control, misfires, evap system & vapor canister, etc. by the PCM.

After replacing the fuel gauge sending unit all the problems vanished no more poor idling, hard starting, engine stopping, etc. and the fuel gauge began to work as it should.

I'm uncertain exactly but believe the PCM needs to know the fuel level to control things such as the evap system and uses this information in conjunction with number of misfires, perhaps idle control, even the o2 sensors, etc. As there's a bunch of computing going on in order to keep the engine running.

Most of the time PCM related problems aren't with the PCM. You need to remember the PCM has a bunch sensor and a few other modules such as TCM, air bags, instrument cluster, etc. sending and receiving data signals from and to the pcm which make computations so your engine is able to run.

If these computations get to a certain point that is likely to cause pollution the PCM will shut down the engine (or sometimes allow the engine to run poorly.)

The primary purpose of a PCM is to reduce pollution and the PCM will sacrifice run-ability to prevent or lower pollution.

______

Much of the PCM activity is done over the CCD (Chrysler Collision Detection) Data Bus between several modules.

I've used OEM Jeep service manuals with PCM and non-pcm troubleshooting procedures that rely on mostly Chrylser's hand held or shop scanner. After reading through the diagnostic procedures I found most of the test and diagnostic could be accomplish manually without a scanner or using an aftermarket scanner with live readout. Testing also often would include using a DMM of which the OEM Chrysler scanner normally has access to this sort of testing and information.

Chrysler OEM scanners are very expensive new the handheld starts at around $6000.00 , but is able to access all the PCM's diagnostics.

I have a couple of scanners, an Innova (OBD1 and OBD2) I paid close to $200.00 a number of years ago, that has live readout and an older Snap-On MT2500 also with live readout that's able to connect to older Jeeps prior to OBD1 has a few diags and test predcures not found with consumer scanners. Doesn't have a graphics display but does ok as a diagnostic tool.

Anyway below is a link with information about the CDD bus which stands for Chrysler Collision Detection. It's a protocol used by the PCM and it's connected modules to talk with each other. If something interferes with the data bus often results in various types of problems.

Powertrain Control Module (PCM)

Transmission Control Module (TCM)

Body Control Module (BCM)

Instrument Cluster (IC)

Controller Antilock Brakes (CAB)

Overhead console

Automatic Temperature Controller (ATC)

Air Bag Controller

http://www.cnblogs.com/shangdawei/p/3570499.html

I went over most everything and could not find the cause of the problem. So I kept driving a couple of weeks of intermittent hard starting, stalling, stopping, etc. (sometimes there wasn't any problems, everything was operating normally and then problems would start again for no apparent reason)

I then remembered that my fuel gauge was also sometimes behaving strangely not always providing the correct fuel gauge readings, would begin to fluctuate, etc.

So I pulled the gas tank and replaced the fuel sending unit as this was likely the problem with the fuel gauge. Once removed I tested to make certain the fuel ga sending unit was faulty as sometimes it's a problem with the wiring and connectors to the fuel pump assembly.

On later model XJ's such as the 98, the fuel gauge sending unit works by sending information directly to the PCM of which controls the fuel gauge, however this information is also used for other things such as idle control, misfires, evap system & vapor canister, etc. by the PCM.

After replacing the fuel gauge sending unit all the problems vanished no more poor idling, hard starting, engine stopping, etc. and the fuel gauge began to work as it should.

I'm uncertain exactly but believe the PCM needs to know the fuel level to control things such as the evap system and uses this information in conjunction with number of misfires, perhaps idle control, even the o2 sensors, etc. As there's a bunch of computing going on in order to keep the engine running.

Most of the time PCM related problems aren't with the PCM. You need to remember the PCM has a bunch sensor and a few other modules such as TCM, air bags, instrument cluster, etc. sending and receiving data signals from and to the pcm which make computations so your engine is able to run.

If these computations get to a certain point that is likely to cause pollution the PCM will shut down the engine (or sometimes allow the engine to run poorly.)

The primary purpose of a PCM is to reduce pollution and the PCM will sacrifice run-ability to prevent or lower pollution.

______

Much of the PCM activity is done over the CCD (Chrysler Collision Detection) Data Bus between several modules.

I've used OEM Jeep service manuals with PCM and non-pcm troubleshooting procedures that rely on mostly Chrylser's hand held or shop scanner. After reading through the diagnostic procedures I found most of the test and diagnostic could be accomplish manually without a scanner or using an aftermarket scanner with live readout. Testing also often would include using a DMM of which the OEM Chrysler scanner normally has access to this sort of testing and information.

Chrysler OEM scanners are very expensive new the handheld starts at around $6000.00 , but is able to access all the PCM's diagnostics.

I have a couple of scanners, an Innova (OBD1 and OBD2) I paid close to $200.00 a number of years ago, that has live readout and an older Snap-On MT2500 also with live readout that's able to connect to older Jeeps prior to OBD1 has a few diags and test predcures not found with consumer scanners. Doesn't have a graphics display but does ok as a diagnostic tool.

Anyway below is a link with information about the CDD bus which stands for Chrysler Collision Detection. It's a protocol used by the PCM and it's connected modules to talk with each other. If something interferes with the data bus often results in various types of problems.

Powertrain Control Module (PCM)

Transmission Control Module (TCM)

Body Control Module (BCM)

Instrument Cluster (IC)

Controller Antilock Brakes (CAB)

Overhead console

Automatic Temperature Controller (ATC)

Air Bag Controller

http://www.cnblogs.com/shangdawei/p/3570499.html

Last edited by Anony; 11-18-2017 at 01:53 AM.

#26

Thread Starter

Member

Joined: Dec 2014

Posts: 167

Likes: 0

From: Ct

Year: 2004

Model: Grand Cherokee

Engine: 4.0

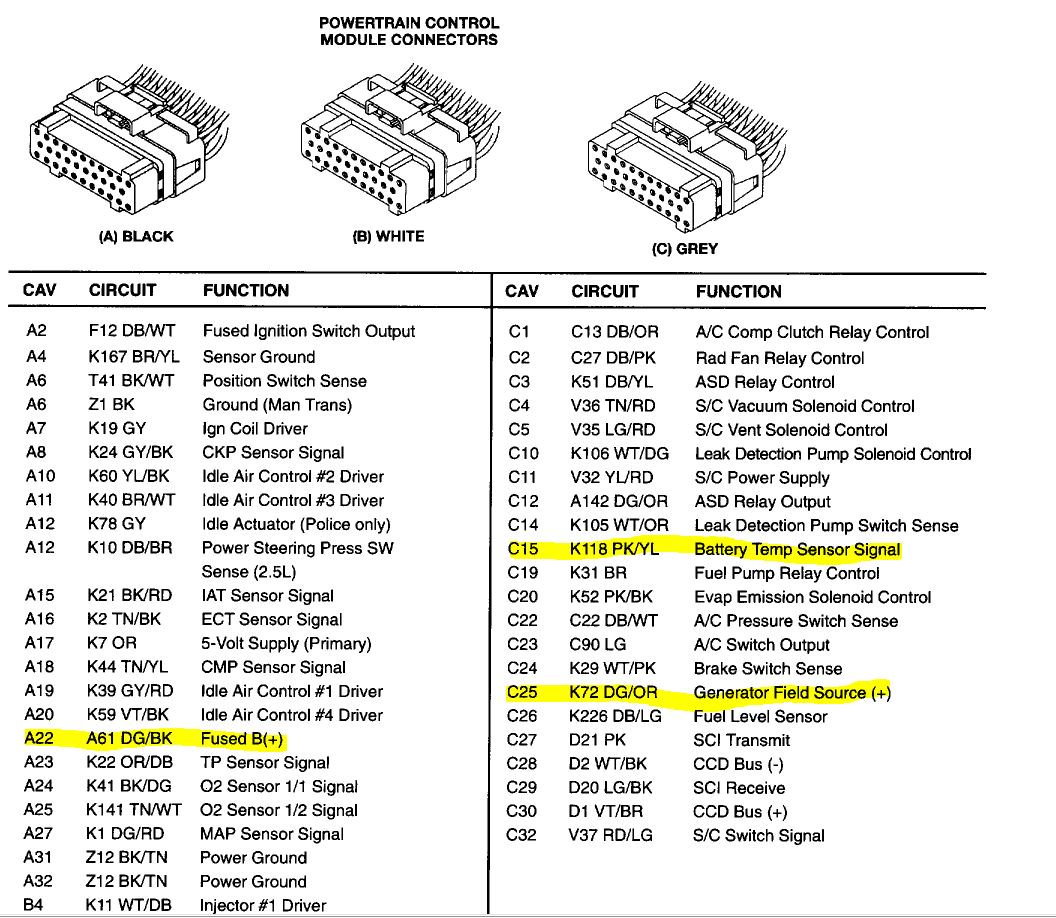

Thank you thats very informative. I hav one last question because dont want to be annoying. The 5 volt supply pin 17 on black connector, is supposed to be constant key on and off?

#27

(GAS)?

A17 K7 18OR 5 VOLT SUPPLY

I think it should be a constant 5 volt supply when the key is on. When the Key is off the voltage should be zero.

However I haven't worked directly with the PCM and sensors in a few years. IIRC the PCM has a built in 5 volt power supply it uses to provide power to sensors that work from 5 volts. A sensor then usually operates with another data line to the PCM that monitors the sensor. The dataline provides information for the PCM.

I would need to review the schematics to recall specific details of the 5 volt system.

The last time I messed with the PCM plug(s) was during testing of field term lines and grounds from PCM plug to the alternator, when having problems with the alternator and charging system.

Which turned out to be a 3rd bad AC-Delco re-manufactured alternator. So I found a new Mopar OEM Alternator. (Rock auto gave me a refund instead of another one of their remans)

It's getting late, near bedtime but can look into it further for more details sometime tomorrow if needed.

Last edited by Anony; 11-18-2017 at 02:40 AM.

#28

Thread Starter

Member

Joined: Dec 2014

Posts: 167

Likes: 0

From: Ct

Year: 2004

Model: Grand Cherokee

Engine: 4.0

You're talking about A17 on the POWERTRAIN CONTROL MODULE - C1

(GAS)?

A17 K7 18OR 5 VOLT SUPPLY

I think it should be a constant 5 volt supply when the key is on. When the Key is off the voltage should be zero.

Yes

However I haven't worked directly with the PCM and sensors in a few years. IIRC the PCM has a built in 5 volt power supply it uses to provide power to sensors that work from 5 volts. A sensor then usually operates with another data line to the PCM that monitors the sensor. The dataline provides information for the PCM.

I would need to review the schematics to recall specific details of the 5 volt system.

The last time I messed with the PCM plug(s) was during testing of field term lines and grounds from PCM plug to the alternator, when having problems with the alternator and charging system.

Which turned out to be a 3rd bad AC-Delco re-manufactured alternator. So I found a new Mopar OEM Alternator. (Rock auto gave me a refund instead of another one of their remans)

It's getting late, near bedtime but can look into it further for more details sometime tomorrow if needed.

(GAS)?

A17 K7 18OR 5 VOLT SUPPLY

I think it should be a constant 5 volt supply when the key is on. When the Key is off the voltage should be zero.

Yes

However I haven't worked directly with the PCM and sensors in a few years. IIRC the PCM has a built in 5 volt power supply it uses to provide power to sensors that work from 5 volts. A sensor then usually operates with another data line to the PCM that monitors the sensor. The dataline provides information for the PCM.

I would need to review the schematics to recall specific details of the 5 volt system.

The last time I messed with the PCM plug(s) was during testing of field term lines and grounds from PCM plug to the alternator, when having problems with the alternator and charging system.

Which turned out to be a 3rd bad AC-Delco re-manufactured alternator. So I found a new Mopar OEM Alternator. (Rock auto gave me a refund instead of another one of their remans)

It's getting late, near bedtime but can look into it further for more details sometime tomorrow if needed.

#29

I believe that's normal. When you turn the key on the PCM supplies 5 volts to a system that powers sensors that run off 5 volts.

Attached is a pic of the modules connected to the CCD Bus.

I'll look around I seem to remember having a diagram of the 5 volt system.

I also have other overview diagrams of the Jeep's electrical system. Attached are some diagrams that include parts of the 5 volt system that's spanned over three pages.

Attached is a pic of the modules connected to the CCD Bus.

I'll look around I seem to remember having a diagram of the 5 volt system.

I also have other overview diagrams of the Jeep's electrical system. Attached are some diagrams that include parts of the 5 volt system that's spanned over three pages.

Last edited by Anony; 11-18-2017 at 02:42 PM.

#30

Based on my experience working on my grandson's 2001 XJ, and reading through all that you've done, the next thing I would do is buy some Deoxit spray contact cleaner. Then I would disconnect and spray both sides of each electrical connector in the engine compartment (in particular the connectors for the camshaft position sensor, PCM, IAC, TPS, MAP, and ECT) , and underneath (in particular the VSS [at rear of transfer case] and crankshaft position sensor). My reasoning is that an input sensor's connector is likely not making proper contact thus disrupting the PCM's output signals.