Rear crossmember/brace bumper build.

#1

Thread Starter

CF Veteran

Joined: Jan 2013

Posts: 19,216

Likes: 40

From: west chester, pa

Year: 1999

Engine: 4.0

Well I mangled my rear bumper against backing against a tree at a wheeling trip. Preventing my hatch from opening. Last week, after looking at it for a while, I decided to unbolt the bumper and take it off. After thinking for a while, I decided to build a crossmember or a brace. It will have uniframe tie-in as well as extra tie ins on the cross member.

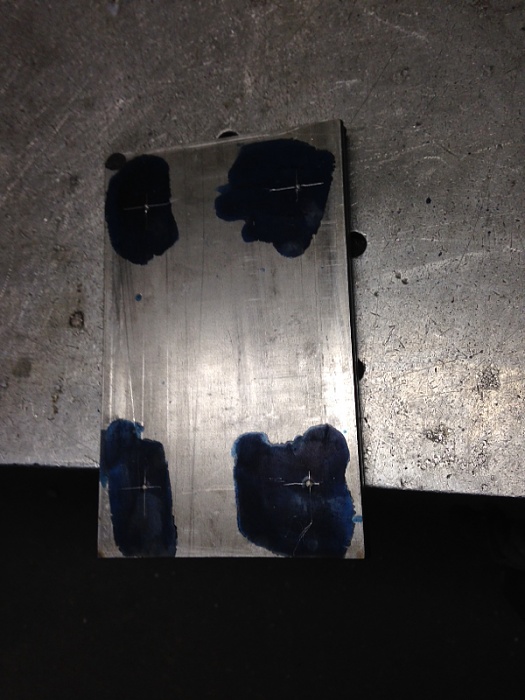

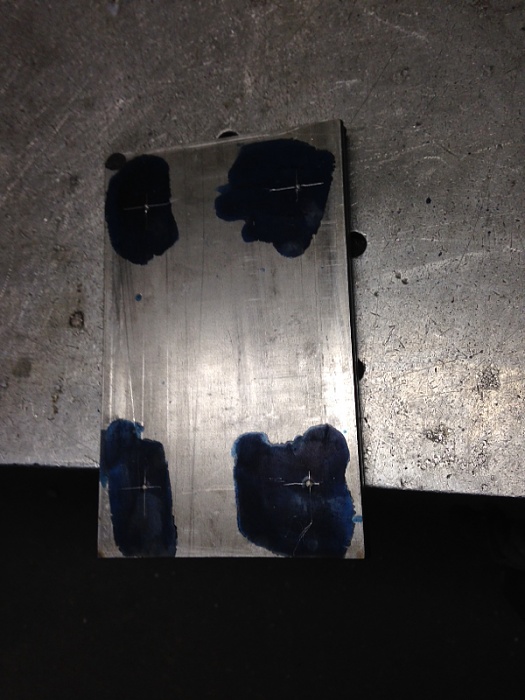

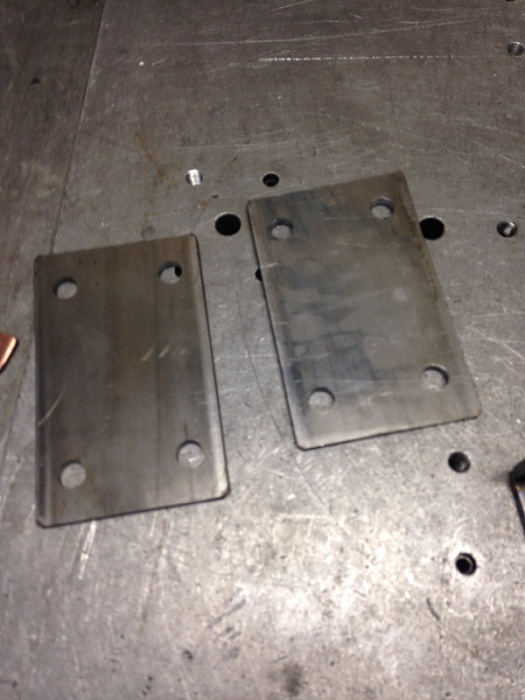

I noticed there's more holes on the sheet metal between the uniframe and I decided I ll utilize those holes just for extra measure. After measuring bunch of mounting holes and other holes. I laid it out on a 1/4x4" bar with layout fluid and scratched where I wanted the holes to be located, punched with a center and drilled them out.

This is what I ended up with.

I decided I ll have brackets behind the sheet metal to further sandwich the brace together. So I took 1/4x4" bar, cut to size, and had it bent on the press brake at work. Drilled holes and welded nuts on it.

I decided I ll have 2x4 tubing cut and notched to fit inside the frame rails, and that will be welded to the brace. Today I took the gas tank skid plate and my hitch reciever down, so I can have more room to work on the area.

My homemade shackle relocation brackets is in my way, because I needed to access inside the shackle box to put a sandwiching plate with nuts welded on it as well. I ll do that the other time when I do frame stiffeners.

Now as for the shackle mounts. I had same material I cut for the shackles on the front bumper. I cut two pieces, marked where I wanted to cut on the corners, and did the final cuts on the bandsaw.

Since I'm gonna use 2x6 tubing as the rear bumper itself, simply welding the shackle mounts directly on the tubing wouldn't cut it... I don't want the shape of the tubing to change if the shackle were pulled on it. Lol. So with that in mind, I decided I ll cut some 1/4x4 plate and weld that with the shackle mounts. It ll go all the way through the 2x6 to the bumper mounting plates.

I'm probably gonna use 3x3 square tubing to weld on the plates and the bumper itself. The shackle tie-in ll be also welded against the 3x3 tubing as well.

I haven't decided on how many bolts I plan to use on the brace against the sheet metal, AND how many bolts I plan to mounting the bumper itself to the brace.

I noticed there's more holes on the sheet metal between the uniframe and I decided I ll utilize those holes just for extra measure. After measuring bunch of mounting holes and other holes. I laid it out on a 1/4x4" bar with layout fluid and scratched where I wanted the holes to be located, punched with a center and drilled them out.

This is what I ended up with.

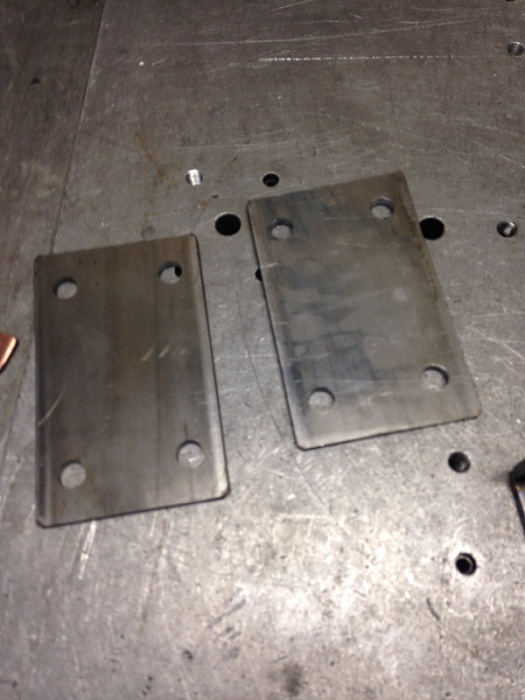

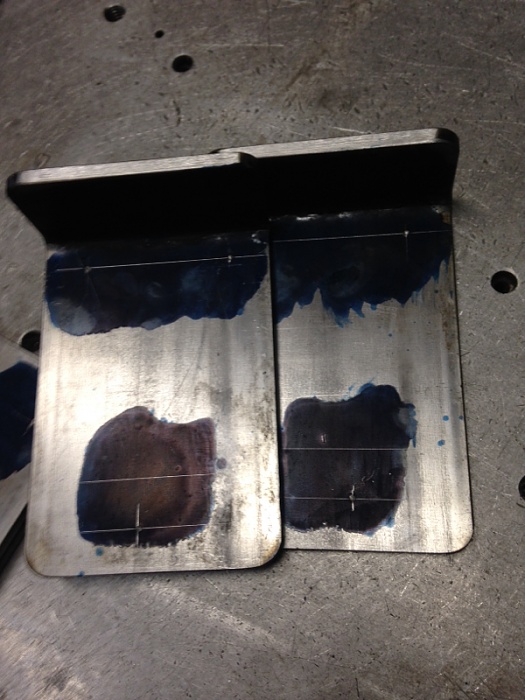

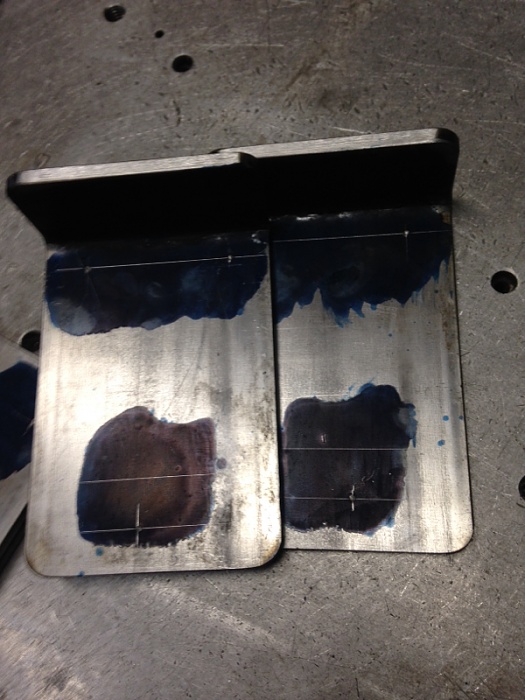

I decided I ll have brackets behind the sheet metal to further sandwich the brace together. So I took 1/4x4" bar, cut to size, and had it bent on the press brake at work. Drilled holes and welded nuts on it.

I decided I ll have 2x4 tubing cut and notched to fit inside the frame rails, and that will be welded to the brace. Today I took the gas tank skid plate and my hitch reciever down, so I can have more room to work on the area.

My homemade shackle relocation brackets is in my way, because I needed to access inside the shackle box to put a sandwiching plate with nuts welded on it as well. I ll do that the other time when I do frame stiffeners.

Now as for the shackle mounts. I had same material I cut for the shackles on the front bumper. I cut two pieces, marked where I wanted to cut on the corners, and did the final cuts on the bandsaw.

Since I'm gonna use 2x6 tubing as the rear bumper itself, simply welding the shackle mounts directly on the tubing wouldn't cut it... I don't want the shape of the tubing to change if the shackle were pulled on it. Lol. So with that in mind, I decided I ll cut some 1/4x4 plate and weld that with the shackle mounts. It ll go all the way through the 2x6 to the bumper mounting plates.

I'm probably gonna use 3x3 square tubing to weld on the plates and the bumper itself. The shackle tie-in ll be also welded against the 3x3 tubing as well.

I haven't decided on how many bolts I plan to use on the brace against the sheet metal, AND how many bolts I plan to mounting the bumper itself to the brace.

#2

Thread Starter

CF Veteran

Joined: Jan 2013

Posts: 19,216

Likes: 40

From: west chester, pa

Year: 1999

Engine: 4.0

Bumper mounting plates

The brackets that go behind the sheet metal that ll tie in the crossmember.

I had to drill out the 4 old weld nuts on the sheet metal so my new brackets will sit flush on the sheet metal. Thank goodness for the unibit.

This is the 2x4 tubing that ll be notched and go in the rails. The holes has been drilled, figured it lol be easier to do that before it get notched.

This is the stock bumper that I mangled.

The brackets that go behind the sheet metal that ll tie in the crossmember.

I had to drill out the 4 old weld nuts on the sheet metal so my new brackets will sit flush on the sheet metal. Thank goodness for the unibit.

This is the 2x4 tubing that ll be notched and go in the rails. The holes has been drilled, figured it lol be easier to do that before it get notched.

This is the stock bumper that I mangled.

#3

Thread Starter

CF Veteran

Joined: Jan 2013

Posts: 19,216

Likes: 40

From: west chester, pa

Year: 1999

Engine: 4.0

#4

Thread Starter

CF Veteran

Joined: Jan 2013

Posts: 19,216

Likes: 40

From: west chester, pa

Year: 1999

Engine: 4.0

#7

Thread Starter

CF Veteran

Joined: Jan 2013

Posts: 19,216

Likes: 40

From: west chester, pa

Year: 1999

Engine: 4.0

I'm still undecided on whether to put a hitch tube on the bumper or keep my hitch receiver.

I use a trailer sometimes and with my reciever it's already too high and need about 8" drop hitch. If I put a tube on the bumper, it would make it so that I would need a 12" drop. Lol

I use a trailer sometimes and with my reciever it's already too high and need about 8" drop hitch. If I put a tube on the bumper, it would make it so that I would need a 12" drop. Lol

Trending Topics

#8

Thread Starter

CF Veteran

Joined: Jan 2013

Posts: 19,216

Likes: 40

From: west chester, pa

Year: 1999

Engine: 4.0

#11

Thread Starter

CF Veteran

Joined: Jan 2013

Posts: 19,216

Likes: 40

From: west chester, pa

Year: 1999

Engine: 4.0

found it. You actually commented on it so u were lying about not seeing the thread. Ha

https://www.cherokeeforum.com/f58/ho...bumper-162482/

https://www.cherokeeforum.com/f58/ho...bumper-162482/

#12

Thread Starter

CF Veteran

Joined: Jan 2013

Posts: 19,216

Likes: 40

From: west chester, pa

Year: 1999

Engine: 4.0

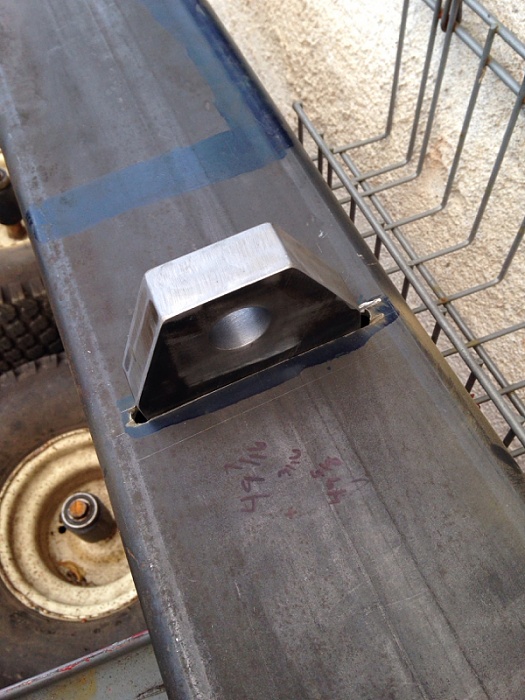

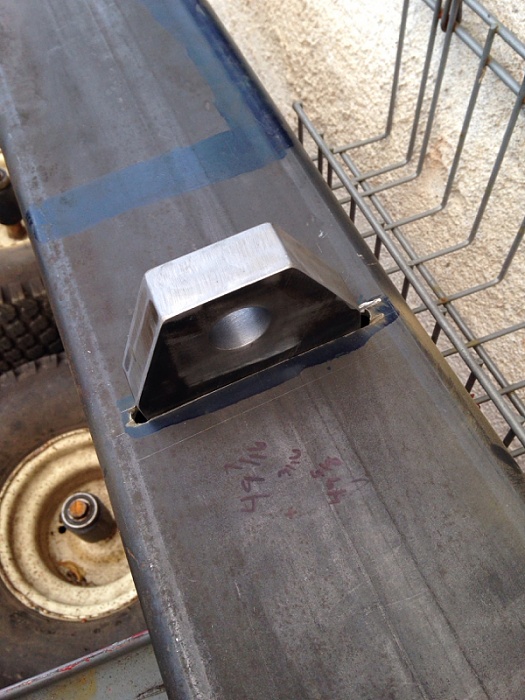

Did some work today. As you see already, the shackle mounts were welded to a piece of 4" flat bar to help tie in. With that in mind, I cut a slot through the 2x6. So it can pass through.

I also notched the 2x4 tubing so it now can have clearance to pass through the frame rails without interference from the fuel filler hose and the leaf spring shackle bolts.

I need to cut the corners of the 2x6 so it ll bevel towards 4" at the ends.

I also notched the 2x4 tubing so it now can have clearance to pass through the frame rails without interference from the fuel filler hose and the leaf spring shackle bolts.

I need to cut the corners of the 2x6 so it ll bevel towards 4" at the ends.

Last edited by XJwonders; 10-18-2015 at 09:56 PM.

#15

Thread Starter

CF Veteran

Joined: Jan 2013

Posts: 19,216

Likes: 40

From: west chester, pa

Year: 1999

Engine: 4.0

Finally opened the holes big enough to slide the tubes in. Looks like my nuts are slightly off. The shackle relocation brackets bolt holes need to be slotted. But I don't feel like taking them off, I think I ll just drill out with step bit.

But yeah the tubes fit perfectly inside the frame otherwise.

But yeah the tubes fit perfectly inside the frame otherwise.